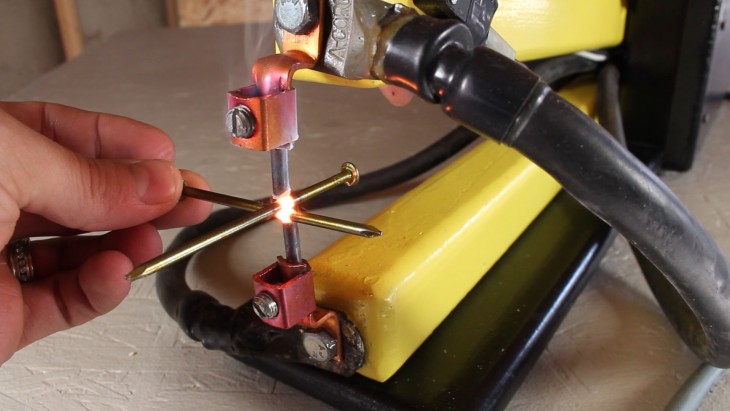

A good welding machine greatly facilitates all metal work. It allows you to connect and cut various parts of iron, which differ in their thickness and density of steel.

Modern technologies offer a huge selection of models that differ in power and size. Reliable designs have a fairly high cost. Budget options usually have a short life.

Our material provides detailed instructions on how to make a welding machine with your own hands. Before starting the workflow, it is recommended that you familiarize yourself with the variety of welding equipment.

Review Content:

Types of welding machine

The devices of this technique differ in several types. Each mechanism has some features that are displayed on the work performed.

Modern welding machines are divided into:

- DC models

- with alternating current

- three phase

- Injector.

The AC model is considered the simplest mechanism that can easily be done independently.

A simple welding machine allows you to perform complex work with iron and thin steel. To assemble a similar design, you must have a certain set of materials.

These include:

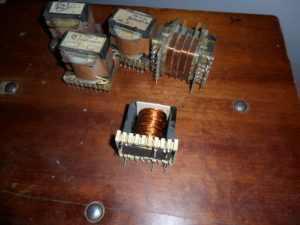

- wire for winding;

- core made of transformer steel. It is necessary for winding the welder.

All these parts can be purchased at specialized stores. Detailed consultation of experts helps to make the right choice.

AC design

Experienced welders call this design a step-down transformer.

How to make a welding machine with your own hands?

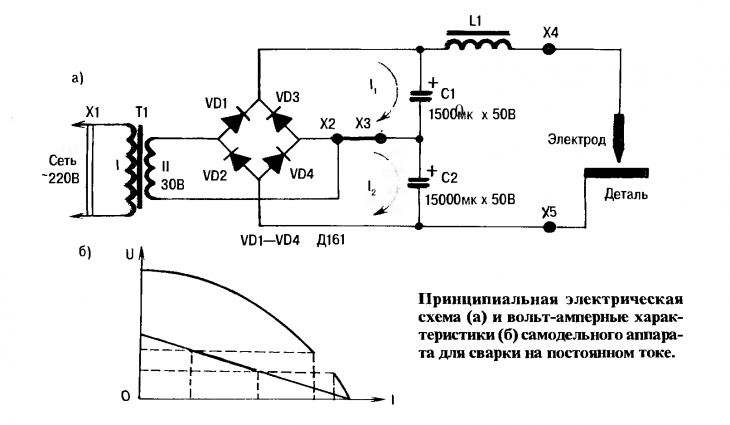

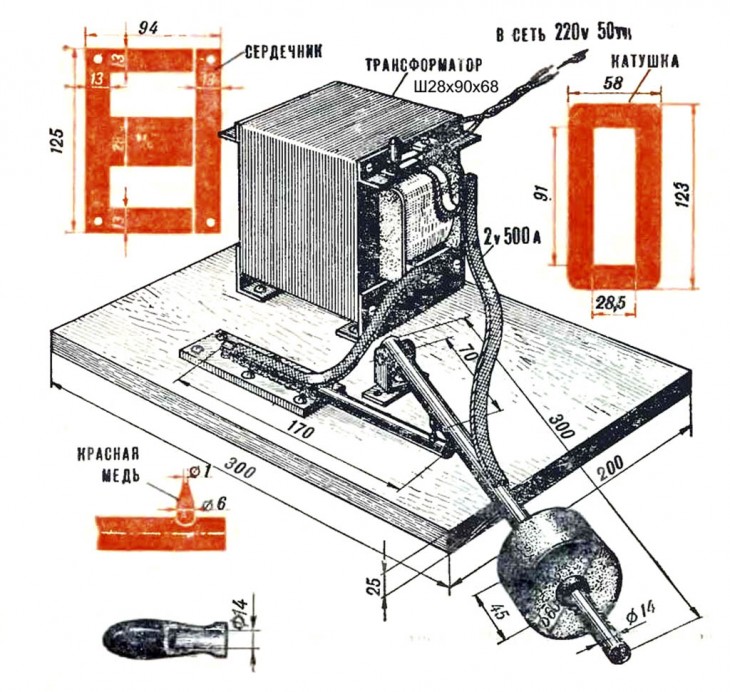

The first thing to do is to make the main core correctly. For this model, it is recommended to choose the rod type of the part.

For its manufacture, plates made of transformer steel will be needed. Their thickness is 0.56 mm. Before proceeding with the assembly of the core, it is necessary to observe its dimensions.

How to calculate the details of the part?

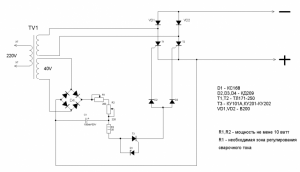

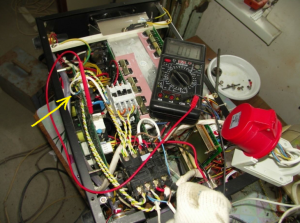

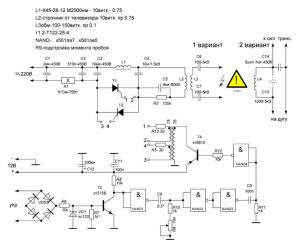

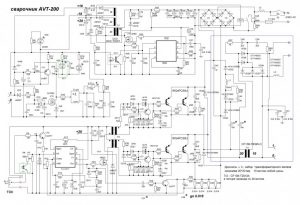

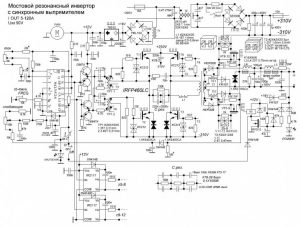

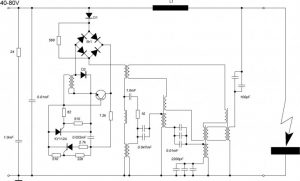

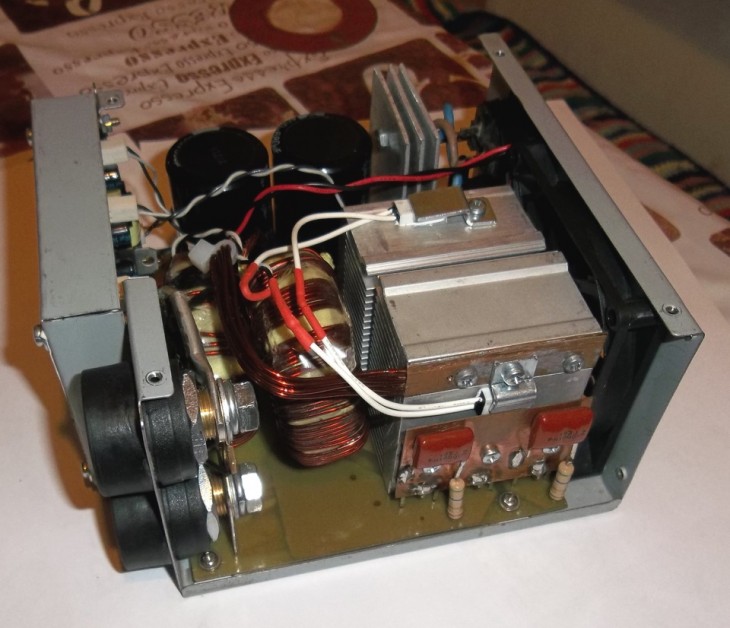

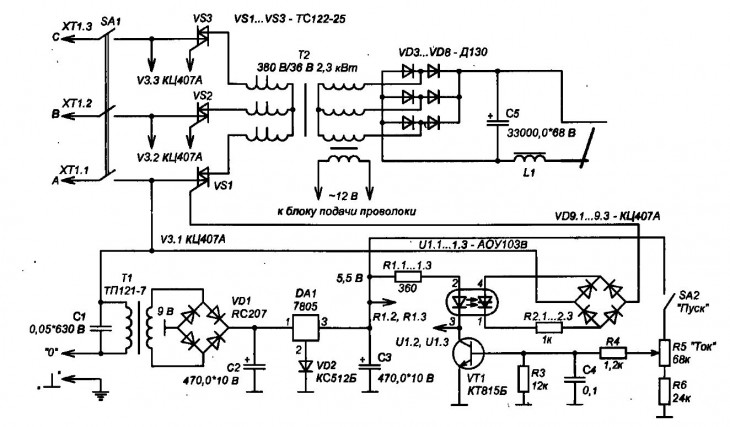

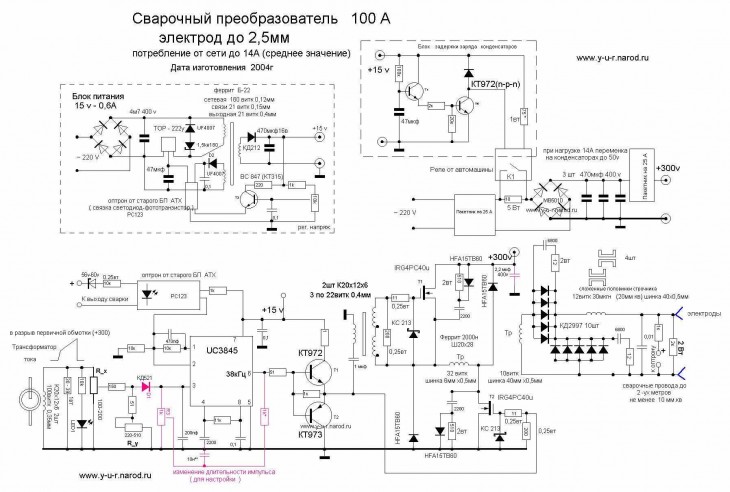

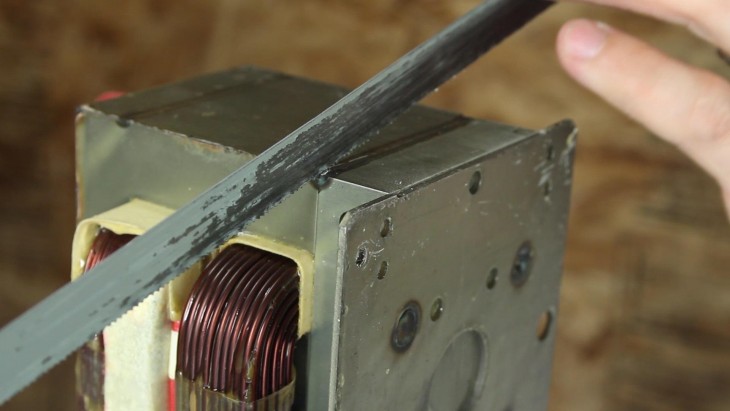

Everything is quite simple. The dimensions of the central hole (window) should fit the entire transformer winding. The photo of the welding machine shows a detailed assembly diagram of the mechanism.

The roll area can be calculated by the formula: S = a * b. The finished calculation result should not be less than 36 square meters. see. The larger the area, the less the device heats up during operation.

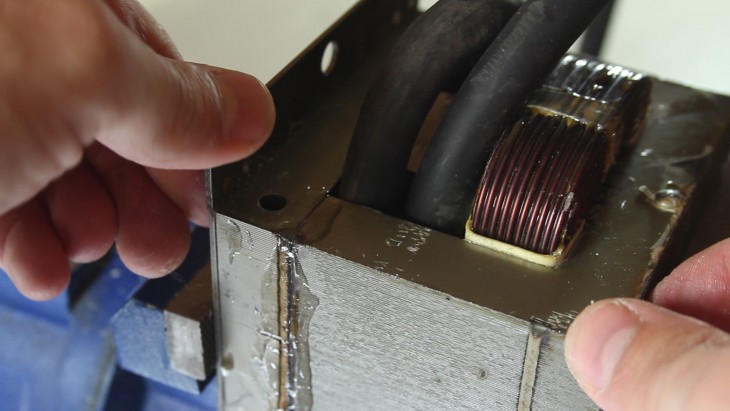

The next step is to assemble the core. To do this, take thin transformer plates, which are interconnected to the required thickness of the part.

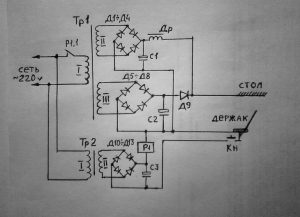

Next, we wind a step-down transformer, consisting of turns of thin wire. To do this, make 210 turns of thin wire. On the other hand, they make a winding of 160 turns. The third and fourth primary winding should contain 190 turns. After that, thick platinum is attached to the surface.

The ends of the wound wire are fixed with a bolt. Its surface is marked with the number 1. The following ends of the wire are fixed in a similar manner with the appropriate marking.

Note!

In the finished design should be present 4 bolts with a different number of turns.

In the finished design, the ratio of winding the winding will be 60% to 40%. This result ensures the normal operation of the apparatus and the good quality of the welding fixture.

You can control the supply of electrical energy by switching wires to the required number of windings. In the process, it is not recommended to overheat the welding mechanism.

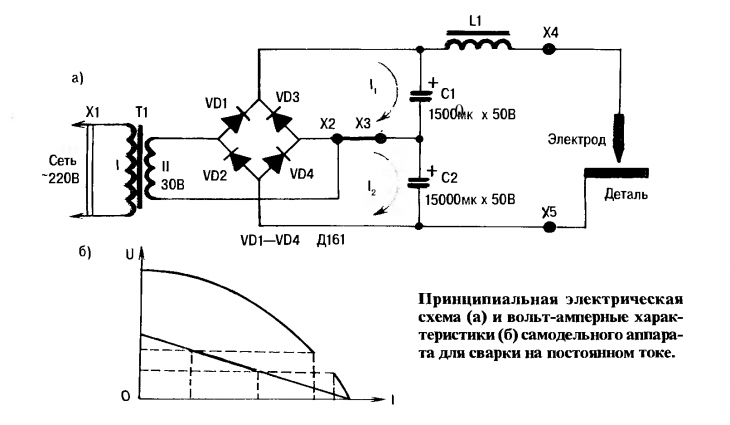

DC apparatus

These models allow you to perform complex work on thick steel sheets and cast iron. The main advantage of this mechanism is its simple assembly, which does not take much time.

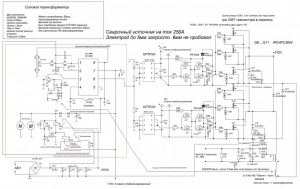

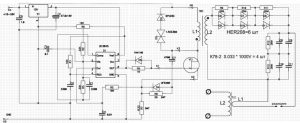

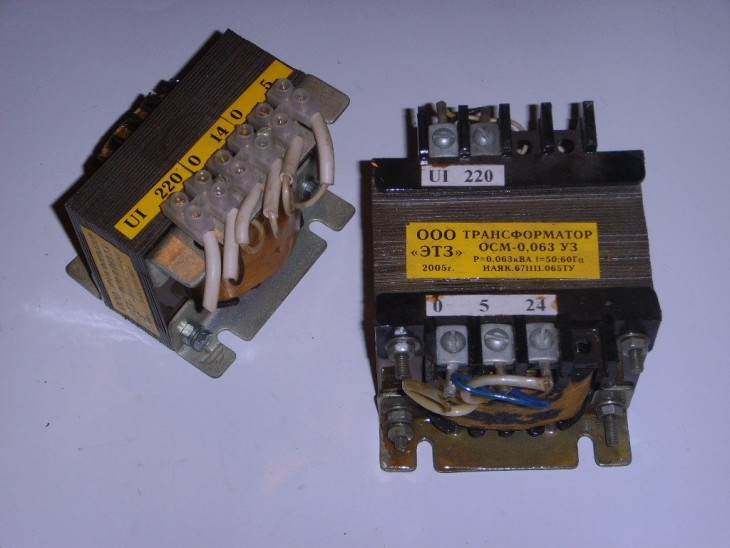

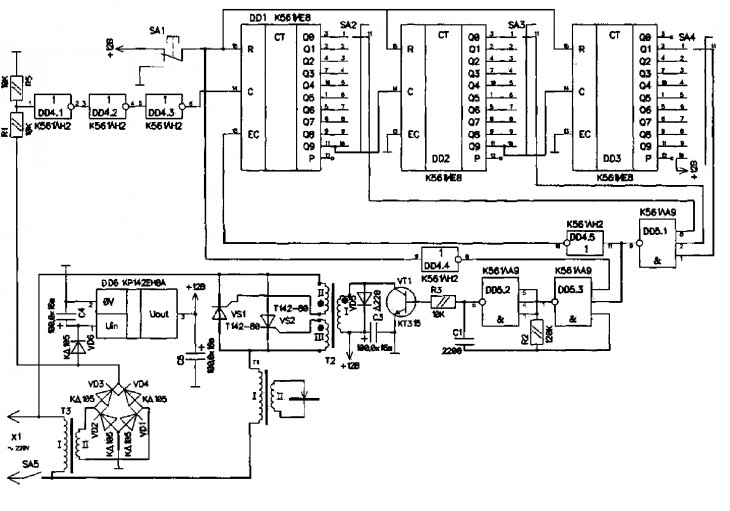

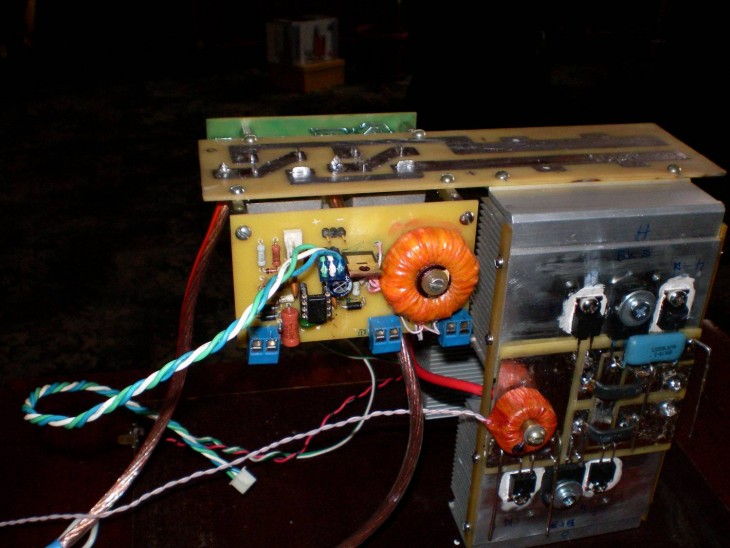

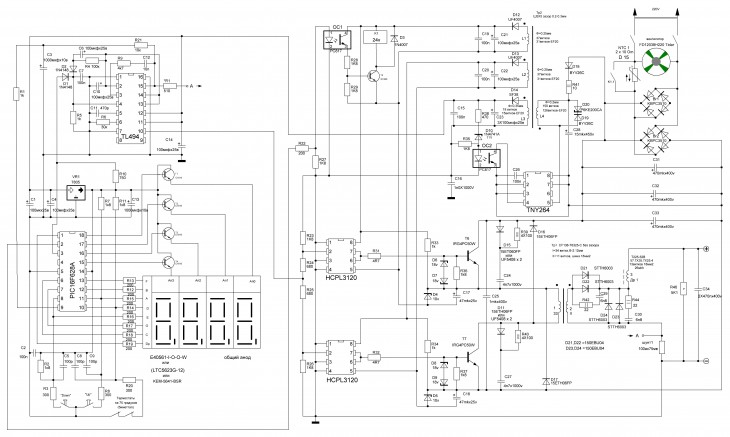

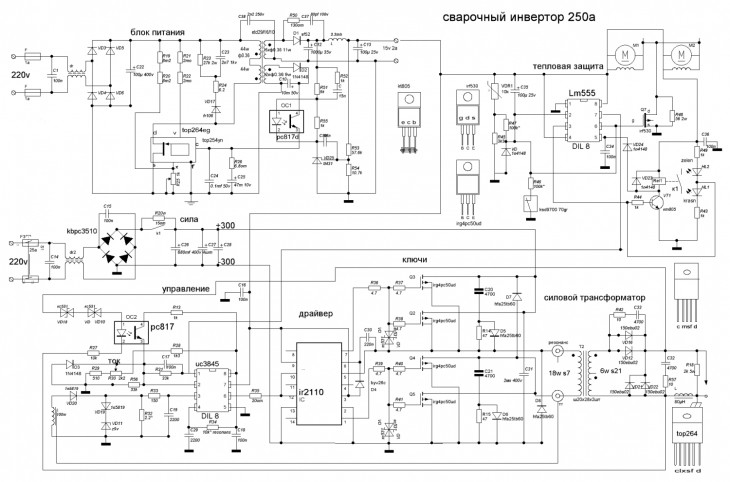

The welding injector is a secondary winding design with an additional rectifier.

Note!

It will be made of diodes. In turn, they must withstand an electric current of 210 A. For this, elements marked D 160-162 are suitable. Such models are often used to work on an industrial scale.

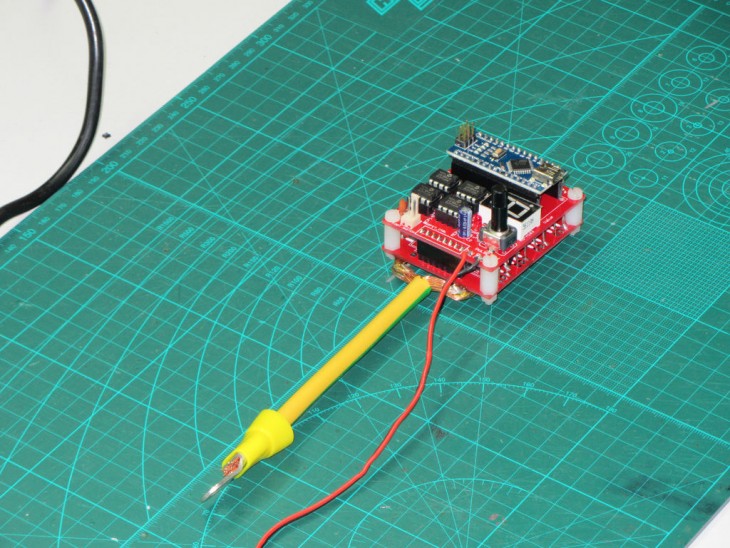

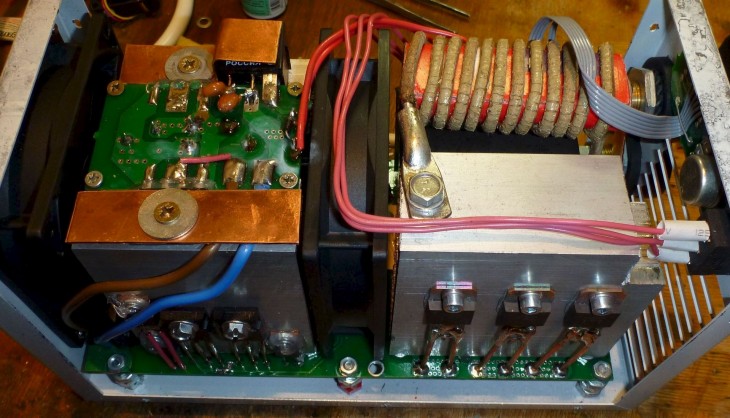

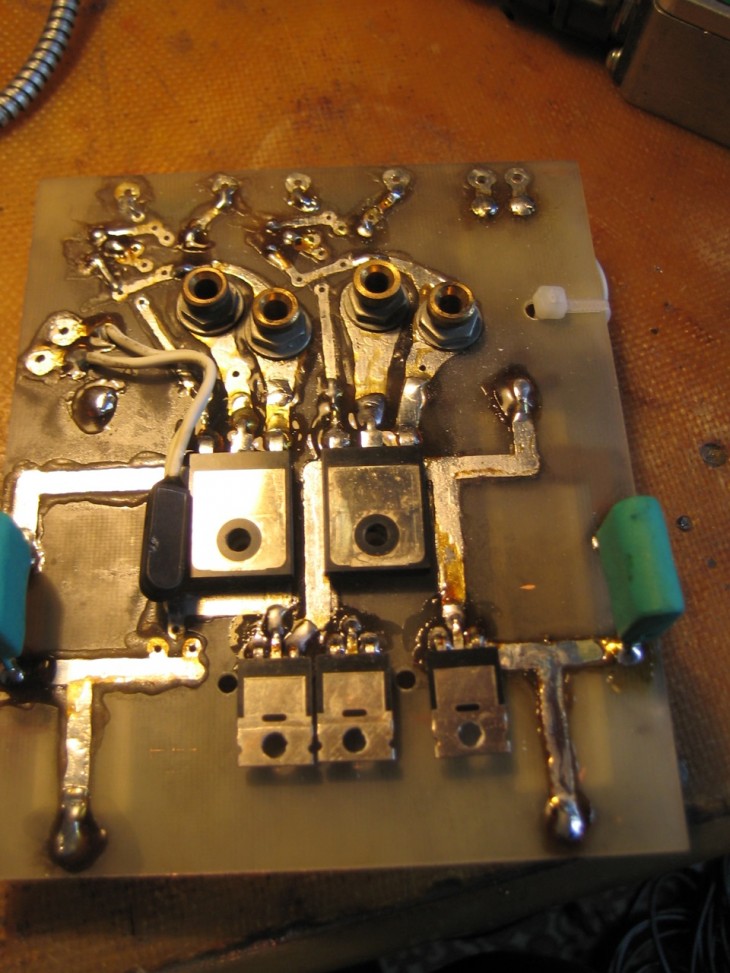

The main welding injector is made of a printed circuit board. Such a welding semiautomatic device withstands power surges during continuous operation.

Experienced welders do not recommend overheating equipment. This can cause the burning of important parts.

Repair of the welding machine is not difficult. It is enough to replace the damaged area of the mechanism. In the event of a serious failure, the primary and secondary windings must be re-run.

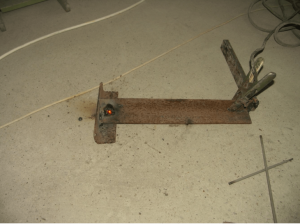

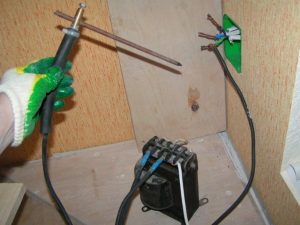

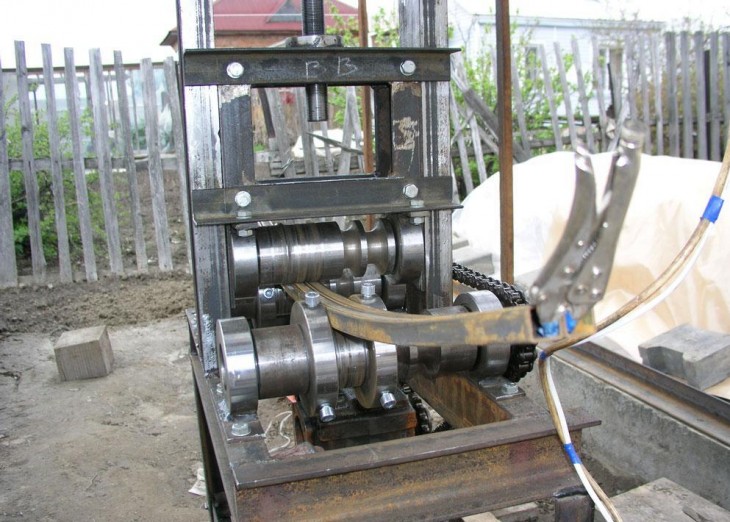

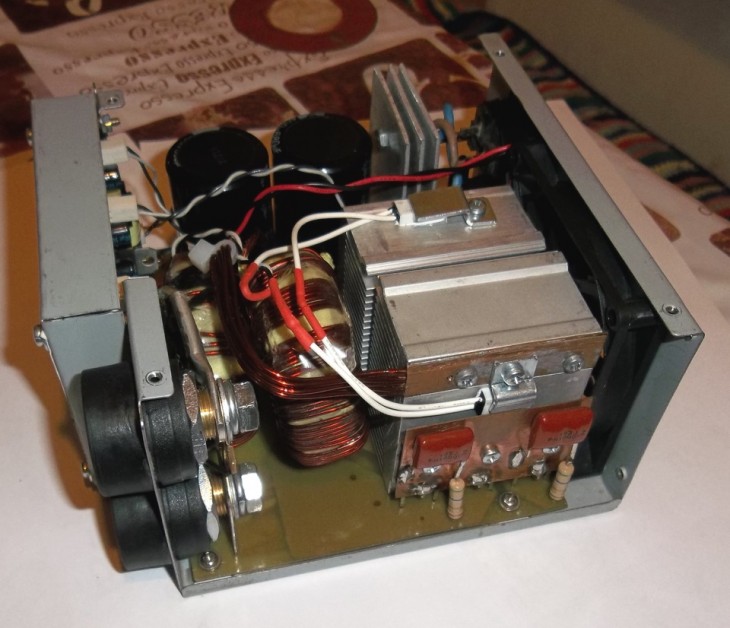

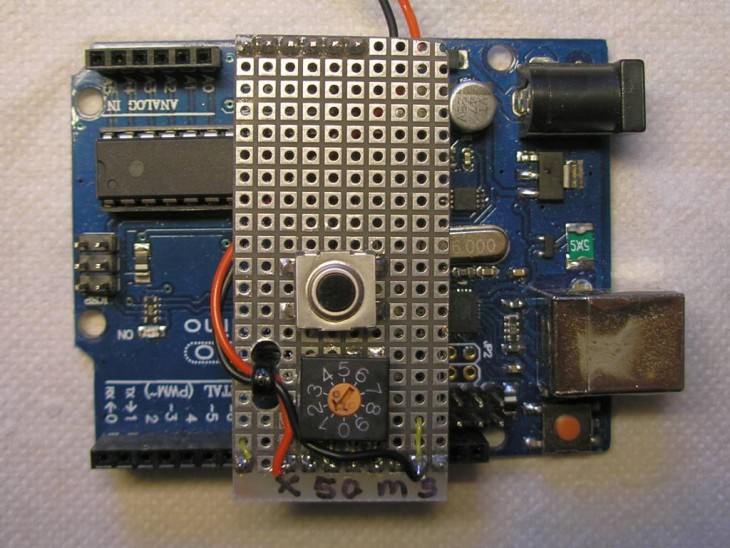

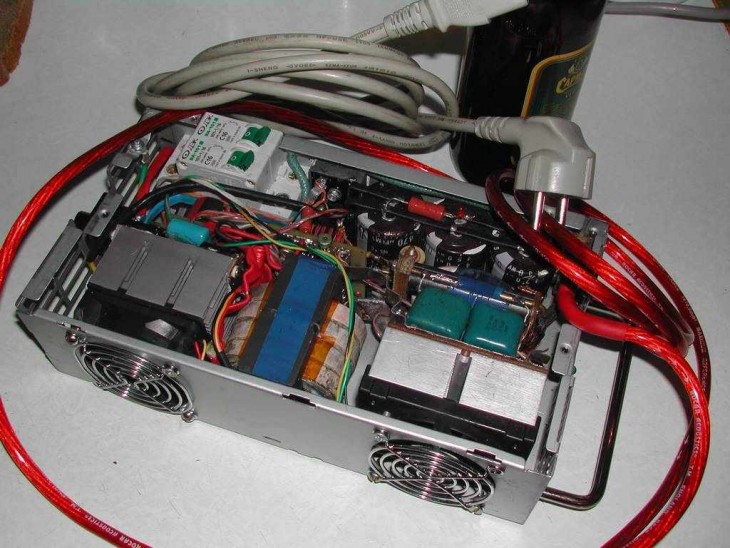

DIY welding machine photo

Note!

Do-it-yourself frame house - 104 photos how to build a durable and reliable house

Do-it-yourself frame house - 104 photos how to build a durable and reliable house

Crafts from the test: 95 photo crafts and secrets of sculpting complex figures

DIY garage - 82 photos of building and summing up all the necessary systems and communications