Bench vice is a necessary equipment in the workshop of any man, without which it is difficult to do in one form or another of work.

They do not have to be located in the garage at all, you can arrange a corner for a vice and at home, for example, using a table or an ordinary stool for this.

Review Content:

Why do we need a bench vise?

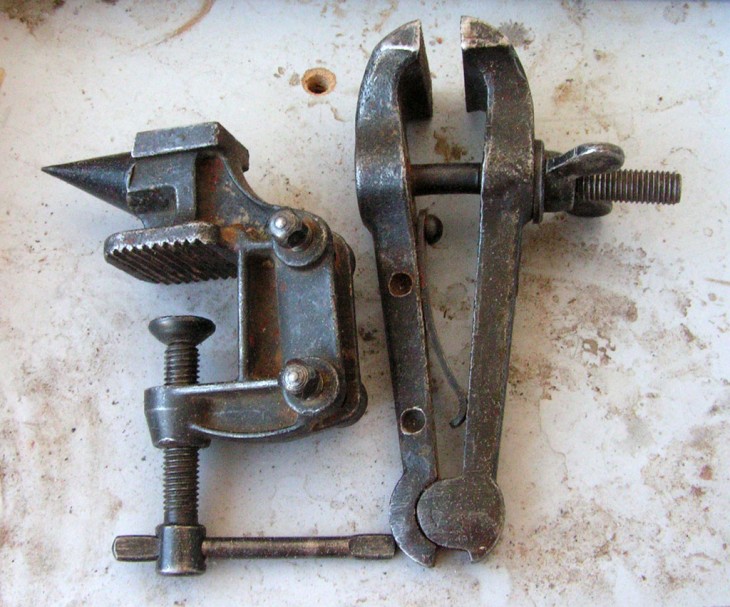

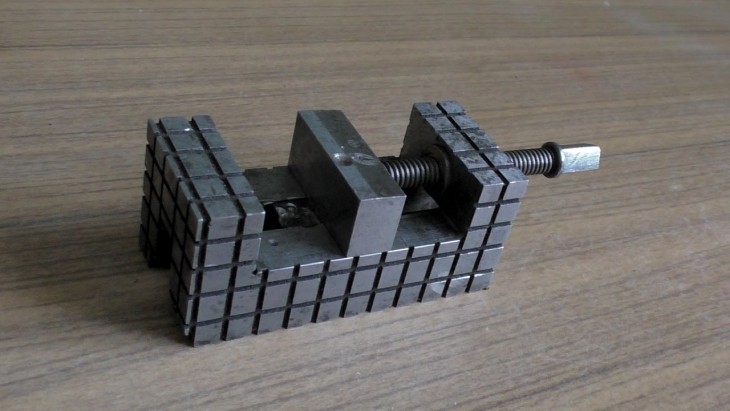

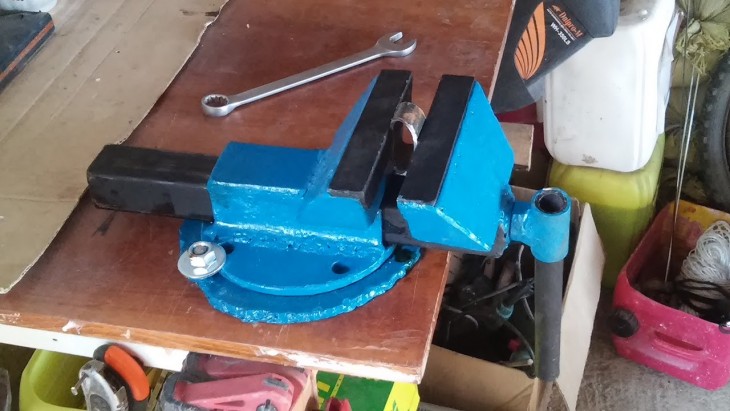

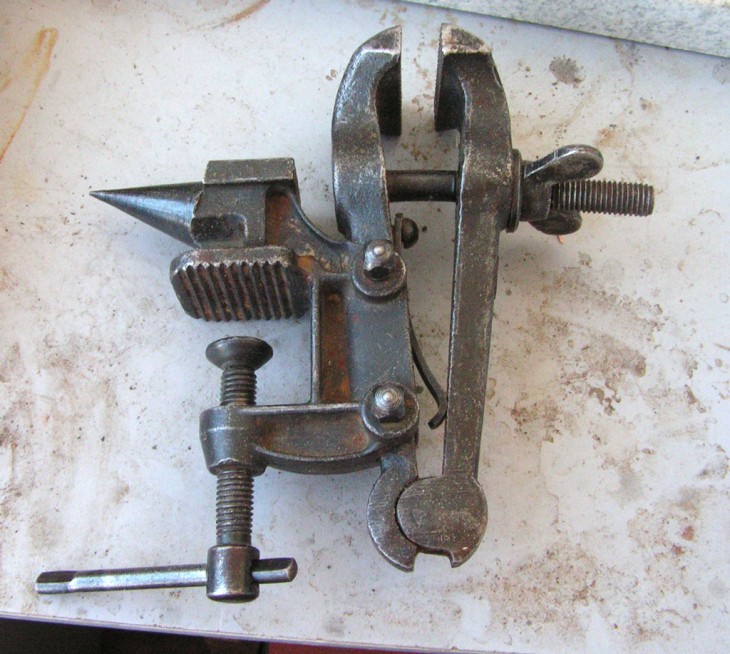

When processing or sharpening any part, it is necessary to fix it firmly and reliably, that is, to keep it in a certain position. The vise photo shows the principle of operation of this equipment.

The parameters and dimensions of the vise are determined depending on what kind of tool you need to firmly hold.

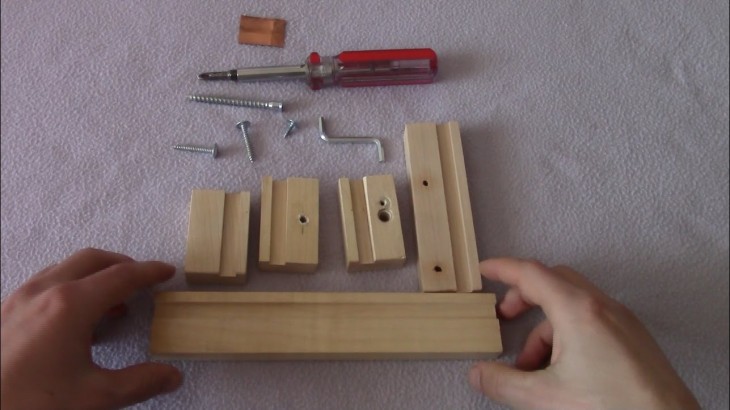

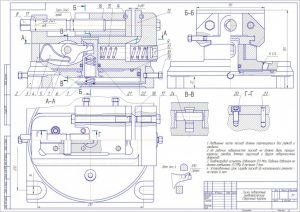

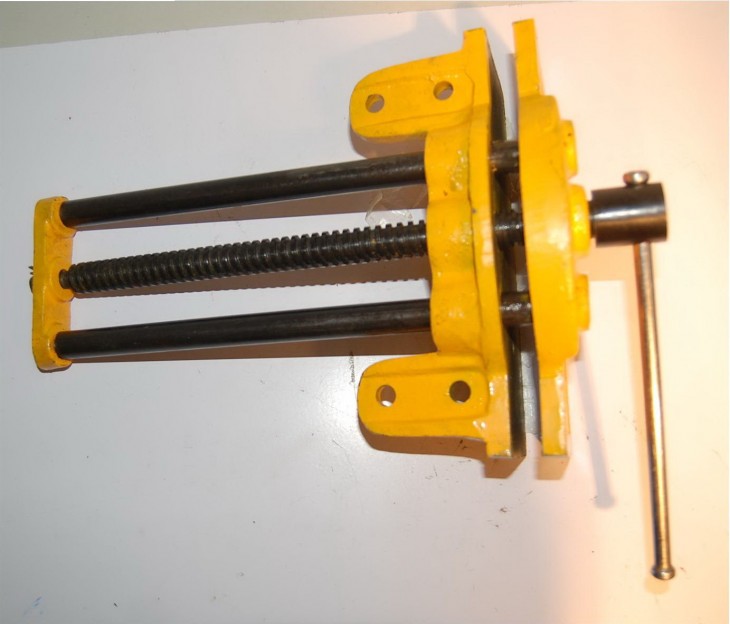

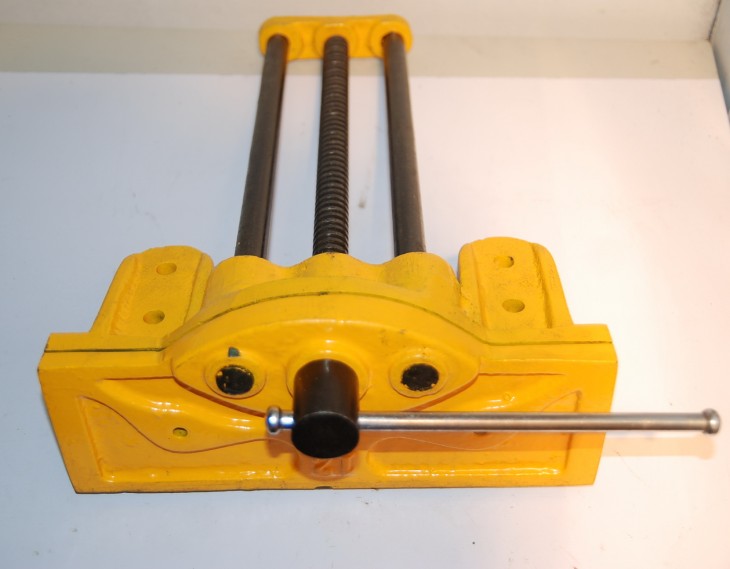

The design of the carpentry vice includes:

- running gear screw;

- handle;

- movable and fixed sponge;

- base plate.

The main types of bench vice

Previously, how to make a vise with your own hands, you need to decide on the choice of work associated with them.

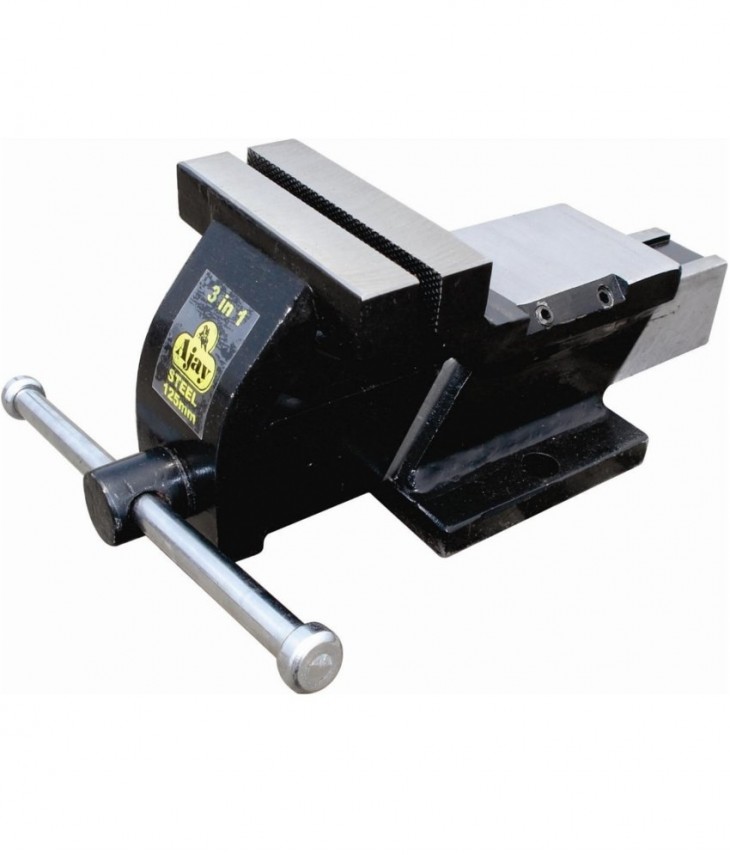

All types of vice are divided into two types:

- non-rotary ones have a simpler design and it is easiest to make them yourself. The part is fixed strictly in one position.

- rotary vice are most often adapted for drilling on the machine. During operation, it is possible to rotate the workpiece without expanding it.

Vise body material is most often made of durable cast iron. It is important to know that cast iron is not designed to be exposed to high temperatures, steel metal is suitable for these purposes.

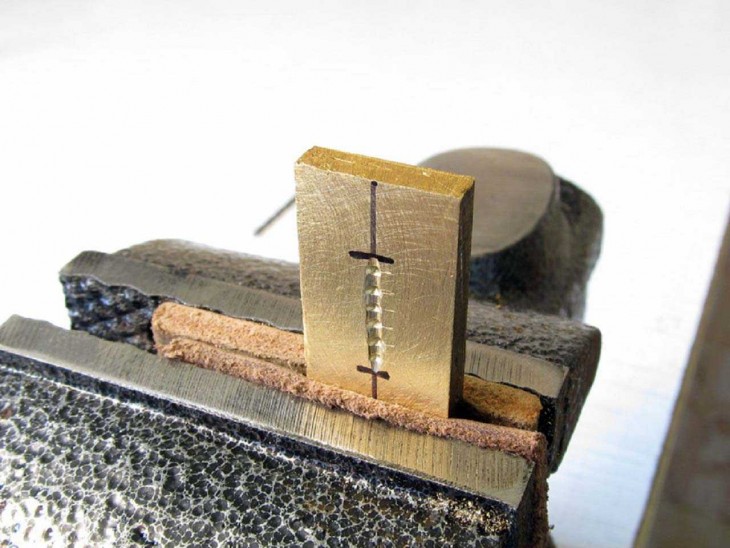

If the work will be carried out with small-sized details, you should not increase financial costs and make compact small vise.

A small vise with a base made of a ball joint is useful in the household for processing very small parts that can be fixed individually. These are mini suction cups mounted on a glass or well polished surface. But they are suitable for rare frivolous work.

Note that it is wise to embed soft attachments on the mounting part to work with soft parts so as not to cause damage to them. A vise with the smallest backlash with fully sponged jaws is ideal.

A vice will significantly save money without a turning mechanism, unless, of course, it is useful in work.

Work on the manufacture of a bench vise at home

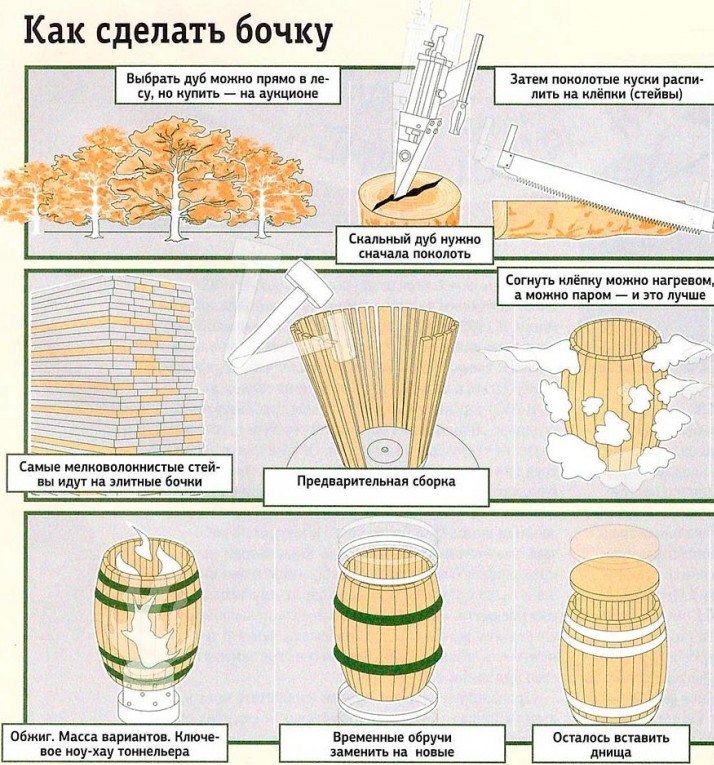

Joiner's vice, self-made at home, will significantly save the family budget significantly than their store-ready “brothers”. And a huge plus is that the product can be made according to personal preferences and for certain individual types of work.

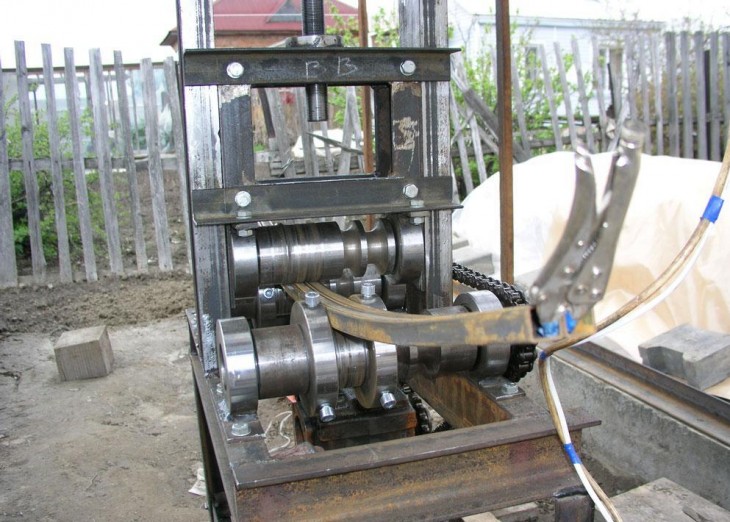

It is absolutely easy to find the material for the construction, it can be: a technical pipe part, a used jack, old lathes, presses, etc.

And if you go to the metal receiving point, there will undoubtedly be a suitable part for a vice, which will cost you a penny.

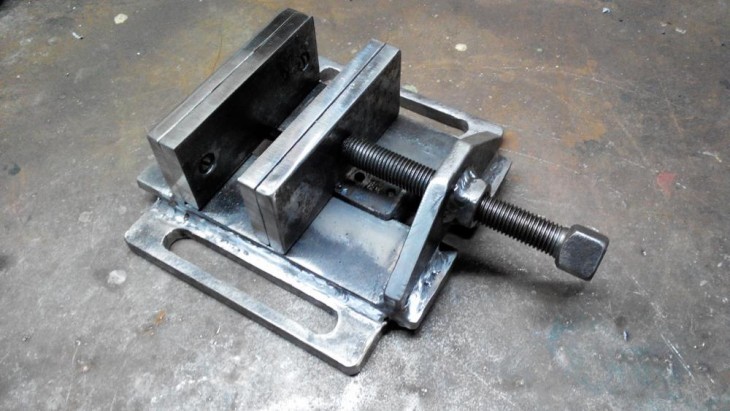

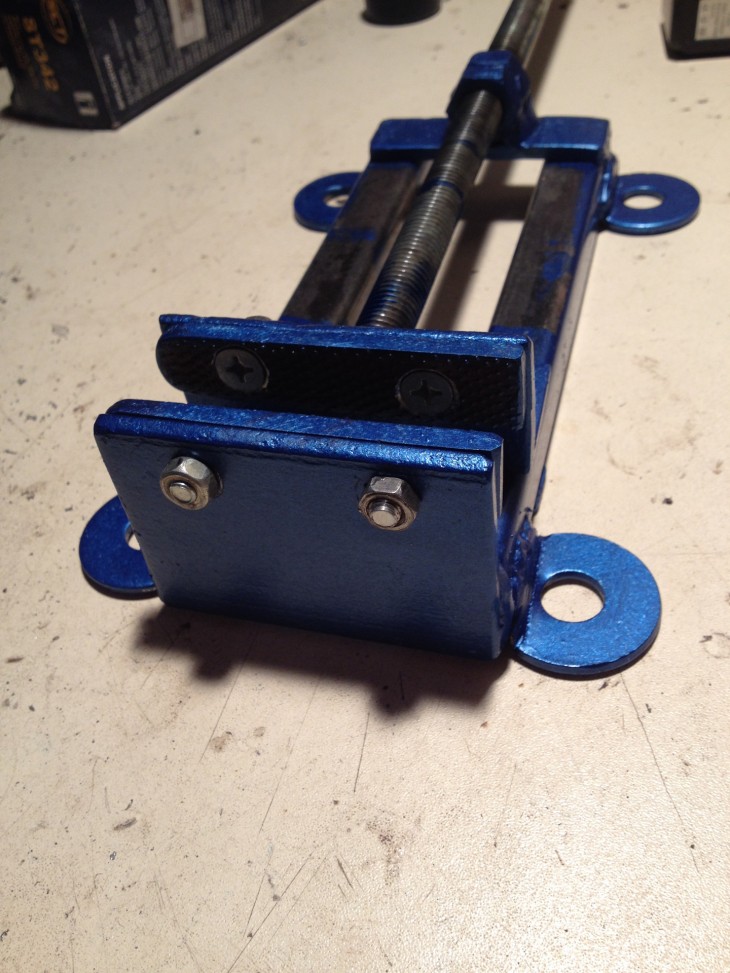

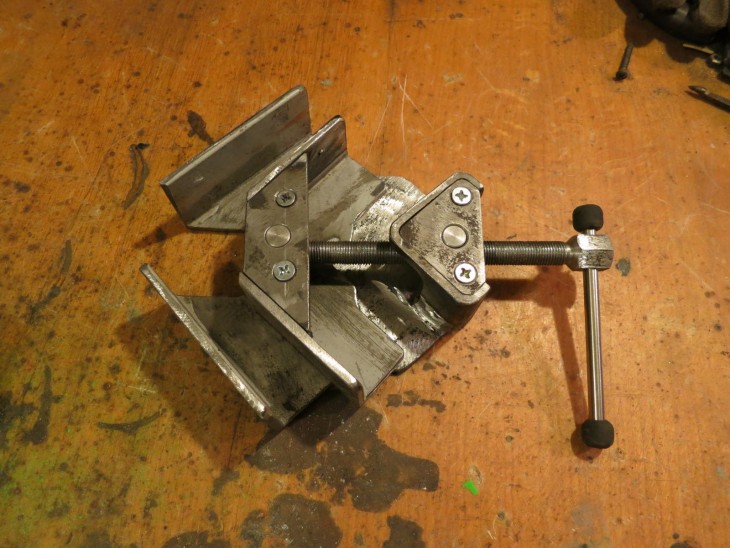

Classic homemade vise

There are many options for a vice, but the most popular and traditional is the type with steel material. Such a vice will be much more reliable than factory-made ones.

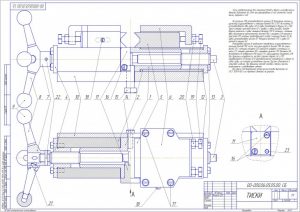

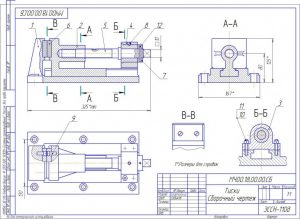

The design consists of:

Note!

- a steel plate of at least 3 mm., but can be much thicker;

- channel external and internal (120 and 100 mm.);

- steel ears;

- 2 turning tools;

- a small segment of reinforcement (rod for the gate);

- a nut (2 pieces), a stud or screw of a certain diameter, which corresponds to a bar;

- a washer (2 pieces) of the same diameter with a lead screw;

- screw pair 335 mm;

- a thick plate is needed to secure the chassis of the screw.

It is necessary to separate the lead screw with washers on both sides of the plate. One of the two washers must be secured with a cotter pin or circlip so that the part is completely collapsible, first you need to weld the thread from the screw to it.

The handle should also be collapsible on one side, and it should be welded on the back with a nut. Flush nut must be welded to the plate with the channel from the screws. To make the channel inside with the screw on the move easier to move, it is recommended to lightly process it with a file.

To the so-called ears made of turning tools, sponges are welded. They are put in place when the lead screw is screwed in, so the ears stand at an ideal distance from each other.

But you can also chain them with wire for greater convenience, so in the future it will be more convenient to fix uneven parts, the shape of which is expanded to the bottom.

Such homemade vice allow you to process larger parts.

Note!

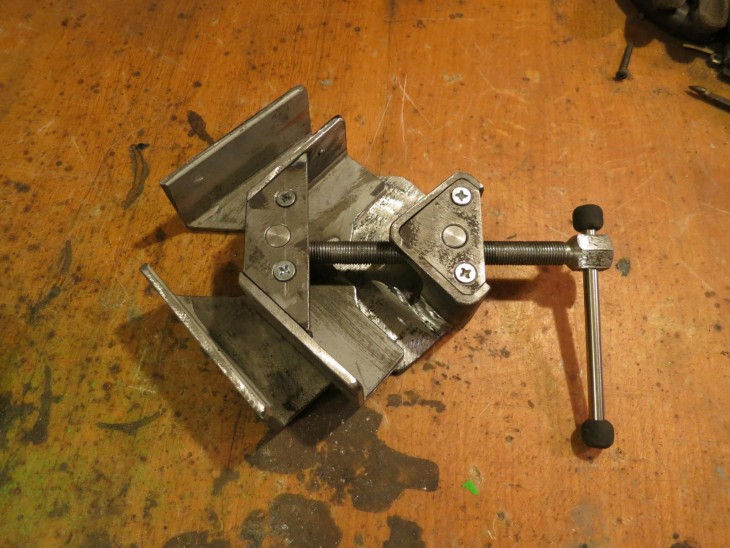

To perform work in the home workshop, it is recommended to choose the simplest fixed vise for the machine.

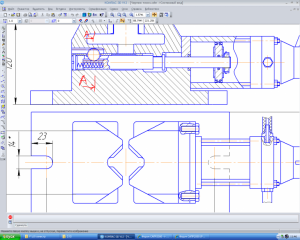

It’s not difficult to make them yourself, you just have to watch the video and recommendations, which can be easily found on the Internet and pre-correctly draw drawings.

DIY vise photo

Note!