It is difficult to imagine a house in which there is no hammer. This tool is an indispensable thing. He will hammer a nail, help crack nuts, and sometimes you can’t do without it in metalwork.

However, there are times that it is broken or one head is left from it. And to perform work that is associated with a hammer is simply necessary.

Therefore, you need to figure out how to make a hammer with your own hands.

Hammer use

The history of the hammer goes back deep into time. It was still used by primitive people. They found him in very different applications. Used in construction, mining, hunting.

By modifying the hammer, you can track how humanity has evolved. Mostly the change affected only the material from which it was created. But the design itself remained unchanged.

There are a huge number of types of hammers that are used in various spheres of human activity. So, it is used in medicine, construction, cooking, locksmithing. In these areas, a hammer is indispensable. However, each sphere has its own specific type of hammer.

The most popular and sought-after is a conventional hammer, which is used in everyday life. Its popularity is explained by the fact that it is multifunctional and universal.

Its main goal is to increase the power of human shock. Besides being needed for hammering nails, it is also an indispensable tool for other construction tools. For such as punch, chisels, chisels.

The following works are carried out with a hammer

- clog nails;

- crush tiles or concrete;

- make holes;

- straighten or bend metal objects.

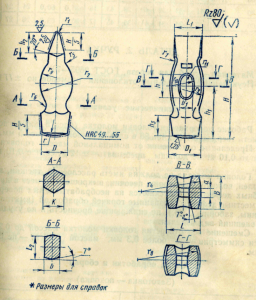

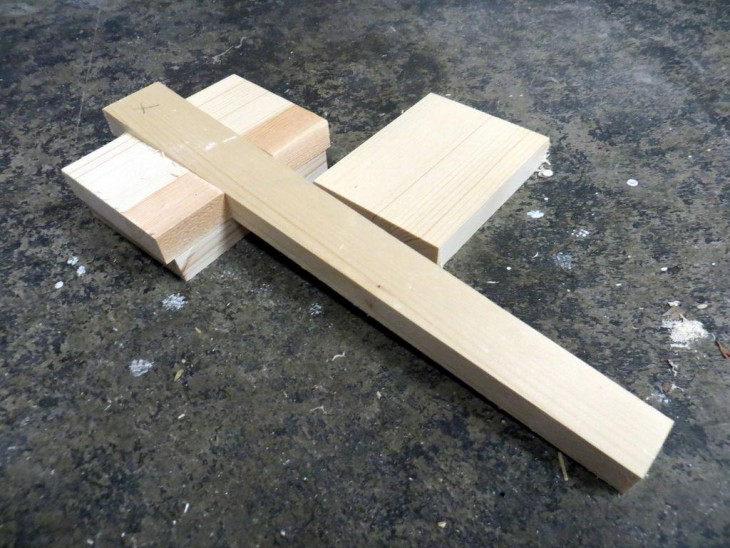

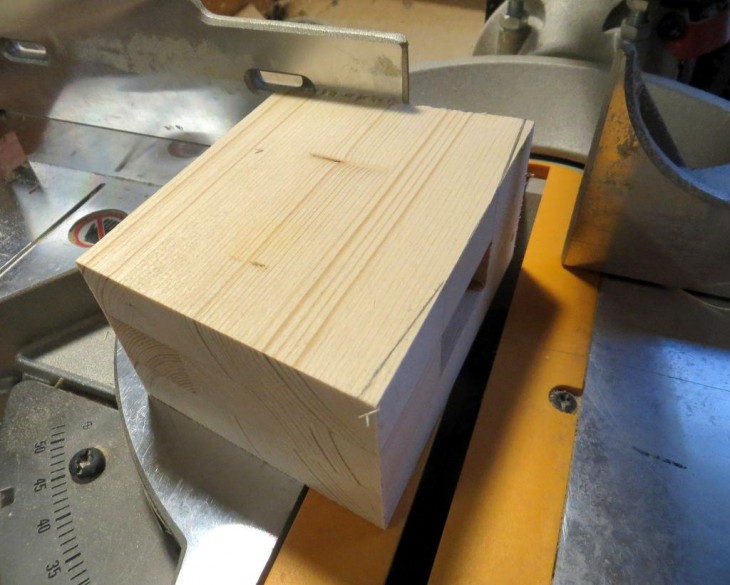

Hammer construction

In the photo of the hammer, it can be seen that it consists of two parts

- lever

- striker.

The handle can be made of the following materials

- wood

- plastic

- metal.

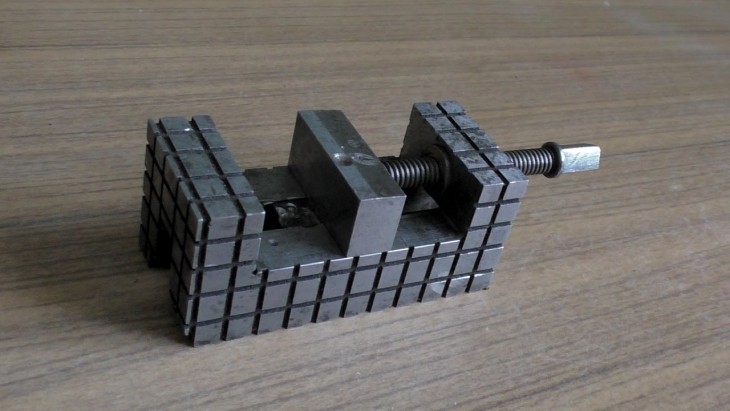

In the production of brisk use

- steel;

- copper;

- lead;

- wood;

- rubber.

Its shape and size depend on the area in which it is used. And the cost of the hammer is greatly affected by the shape of the striker.

A square is much cheaper than a round shape. Since its shock part has a much sharper accuracy, as well as a greater impact power. The speed of any hammer can only be regulated by a person.

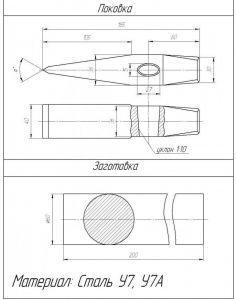

How to make a hammer

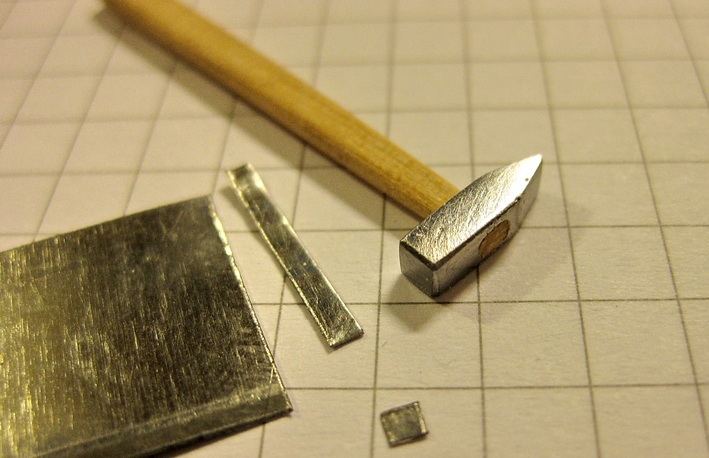

The tool begins to make with the handle. Since the firing pin itself is usually there. To make it at home is problematic. Therefore, do not throw away the old hammer heads.

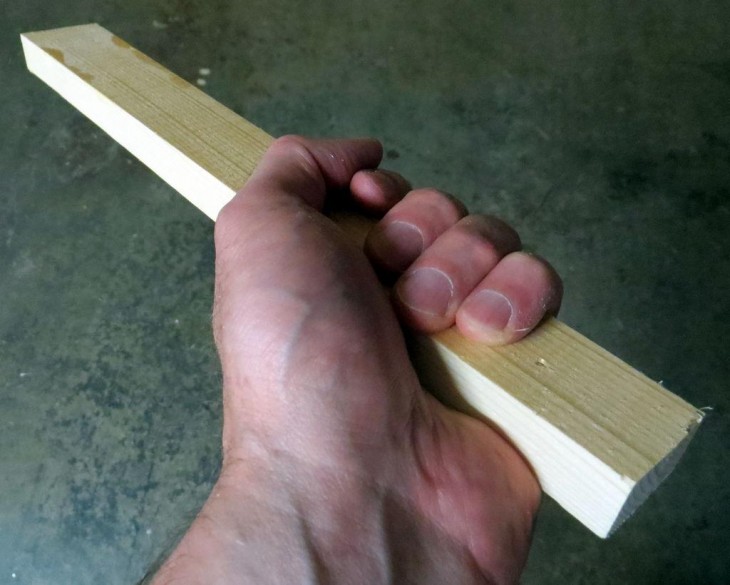

The handle is easiest to make of wood. To do this, come 3t, the following tree species

- Birch;

- maple;

- Rowan;

- beech.

Note!

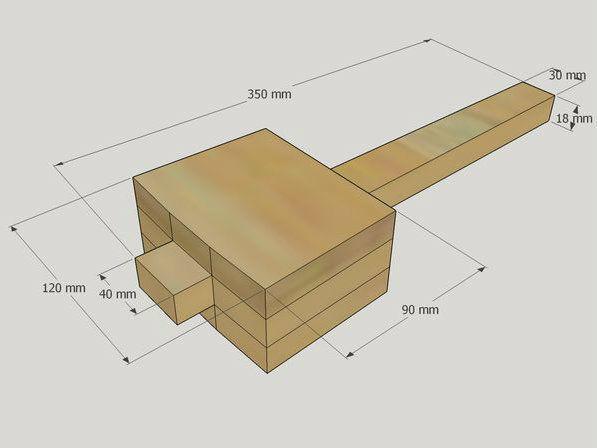

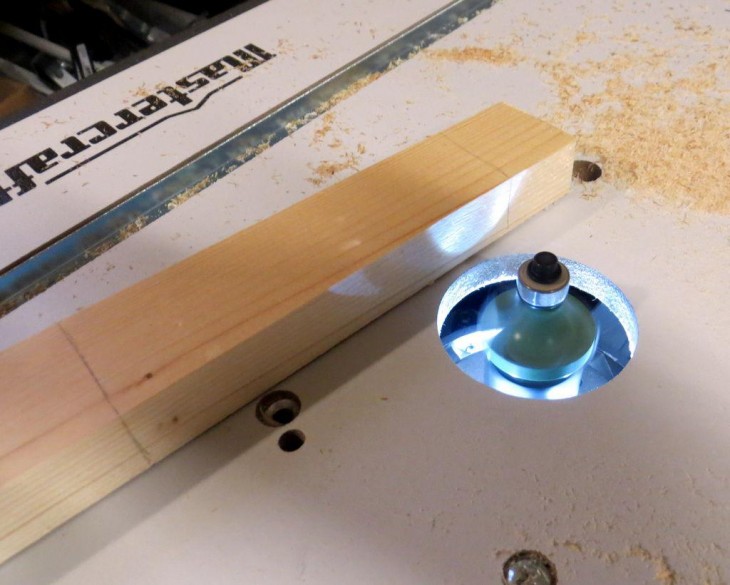

For the manufacture of a block of wood is needed. The size depends on how long the hammer is needed. The handle itself is machined from a block. After that, it is imperative to sand it, so that later there will be no discomfort in the work, and the skin on the hands will not be affected.

The prepared wood needs to be thoroughly dried and then varnished. The drying room is carefully selected. Since it must comply with the basic rules:

- good ventilation;

- lack of a large amount of sunshine;

- constant positive temperature.

It is important that wood cannot be dried with artificial lighting. Since it can be deformed, and its size can change greatly.

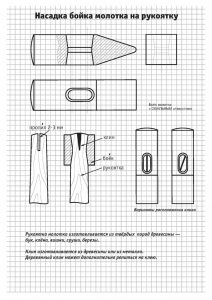

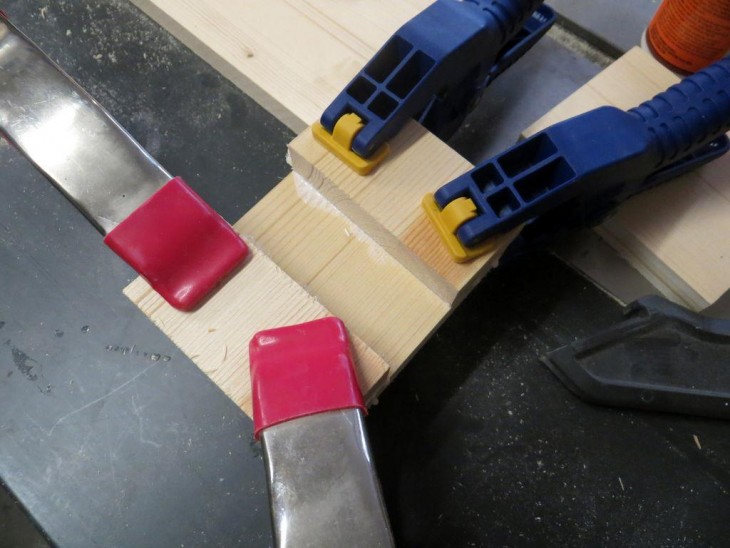

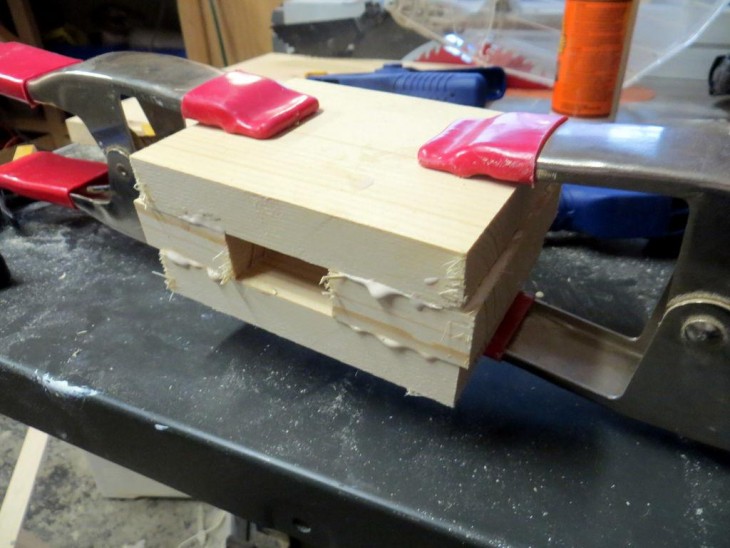

The next stage is the most difficult, it is the connection of the handle with the striker. The tapered end of the handle must be inserted into the hammer head with some effort.

Often there are times that the tip is not suitable in size. In the manufacture of the handle, it turned out a little more. It’s not a big deal. Using the rasp, you can process it to the right size, and then sand it to make the surface smooth.

Note!

The hammer is mounted perpendicular to the base of the handle. In this case, the structure must be kept upright.

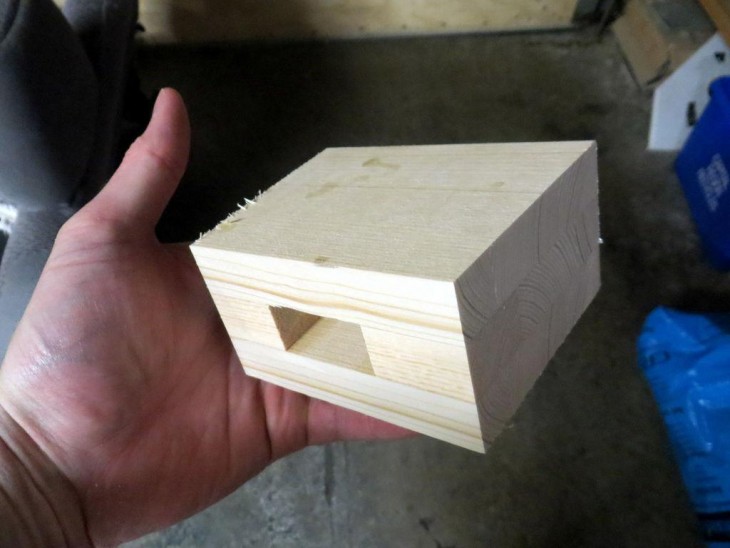

The head is inserted with the help of gradual impacts on a hard surface, until the moment the handle does not fit snugly into the head. Everything, the hammer is ready to use.

Making a hammer yourself is not difficult, the main desire. Of course, you can buy a new hammer in the store, but this does not give a full guarantee that the connection between the head and handle will not break in the new one. Therefore, it is advisable to make a hammer with your own hands.

DIY hammer photo

Note!

Cork crafts: instructions and examples on how to make interesting things (80 photos)

DIY playground - 55 photos of the construction of an entertainment area

DIY toilet - detailed building instructions + 74 photos

Do-it-yourself crib (70 photos): make from various materials (step by step instructions)