A barrel made of wood is an excellent container for storing pickles, as well as wine, because the natural massif is considered an environmentally friendly material that preserves the usefulness, great taste of the products.

A similar thing, like plastic barrels, can be bought in a specialized store.

If you want to create a wood product with your own hands, it will not be difficult.

Array selection

One of their initial tasks is the competent choice of a tree to create a container.

Let's talk about the main varieties used.

Oak

This is the classic and most suitable material in the cooper issue.

The tree is characterized by a huge degree of strength, saturation with antiseptic substances.

It is noteworthy that under the influence of humidity barrels in the cottage of oak exclusively grow stronger over the years, which is why they are characterized by the duration of the operational period.

Another no less important plus of oak is the pleasant smell with which it saturates stored products.

Pine

Refers to soft wood species that can be processed without problems, but less durable in comparison with oak.

The main disadvantage is the aroma of the resin, so containers for pine products are rarely created.

Linden

It is considered a fibrous wood species that can be processed and cut well.

The material is characterized by durability, lack of aroma, does not dry out, which is why lime barrels are recognized as the best when transporting various delicacies.

Aspen

It is considered a durable, inexpensive material with antiseptic properties.

So, aspen containers are suitable for storing a variety of pickles.

One of the important features of this massif is the possibility of excessive swelling, however, in the cooper issue this relates more to the pluses, since it makes it possible to achieve the maximum connection of rivets.

Note!

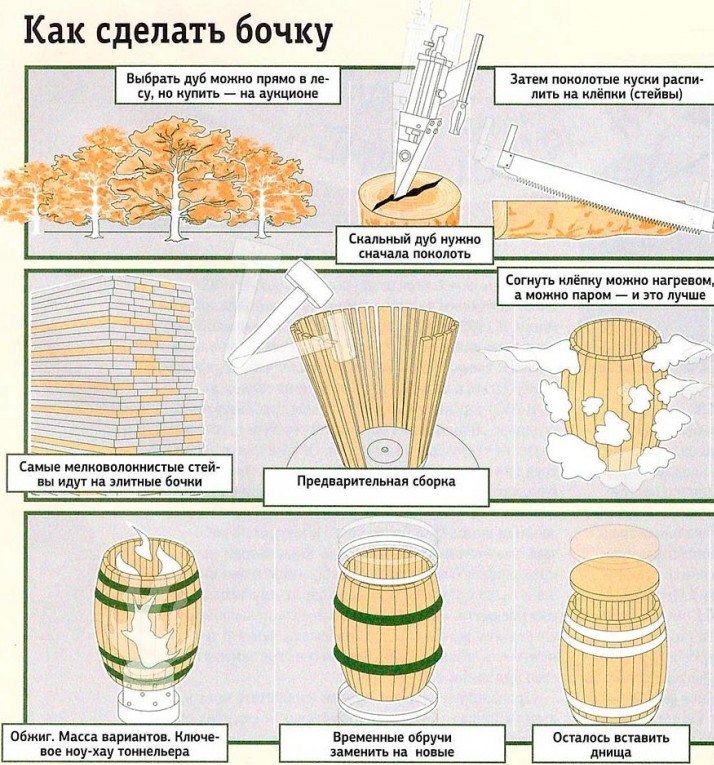

Making staves

The next stage that you want to go through to those who want to learn how to make a barrel with your own hands is the creation of elements.

It is important to start with rivets - tapering to the edges, or of a rectangular type of stitching, which can be sawn or chopped.

The second option is among the most durable, since their fibrous structure is not susceptible to destruction when a tree is split.

As for the creation of a capacity from chipped type rivets, it is complex and needs professionalism.

The main task is to split the pre-prepared workpiece into equal parts, while obtaining a minimum of waste material.

The easiest way to process the material is raw, as in the photo of the barrel below.

Note!

After chopping the required number of rivets, they should be dried by decomposing under a canopy in the heat season.

If artificial drying is required, then thick paper is glued to the ends, then rivets are placed in the oven for one day.

At the end of these steps, the material can be processed.

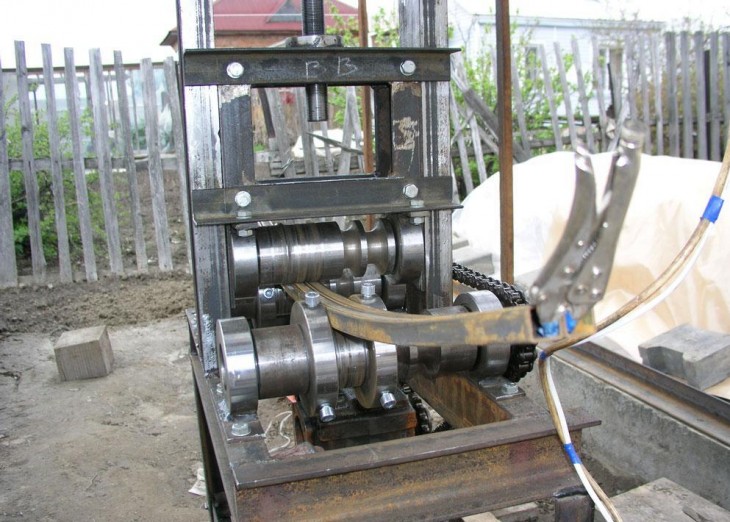

Hoop creation

Also an important task in the manufacture of the barrel is the assembly of rivets, that is, the creation of hoops.

They come in wood or iron.

Note!

A durable option is metal, but its minus is the possibility of rapid rusting.

Therefore, such hoops are used exclusively when it is necessary to obtain a product of a high degree of strength.

Then it is important to collect the barrel, and also to establish the bottom in it.

Soak

Having gone through all these processes of self-manufacturing a barrel, it remains to put it into operation.

Before using the product, it must be processed.

And it doesn’t matter if you are going to store food in a container, or create watering from a barrel, or shower from a barrel.

After all, the product should be well sealed and not exude unpleasant odors.

Therefore, first of all, it is important to rinse the container to eliminate residues of sawdust, debris, as well as numerous tanning elements.

Rinsing is carried out until complete elimination of extraneous odors and maximum water purification.

Then the container is steamed for disinfection and increase sealing. For this purpose, the barrel is filled with steep boiling water, leaving it inside until it cools. Repeat this process twice.

Once the container has been steamed, it must be soaked.

In most cases, the procedure takes approximately thirty days, while it is important to change the water almost every other day.

At first, leaks are not excluded, which is considered the norm. However, it is important to make up water in this case.

In the end, I want to note that a barrel created manually is a good option for home use.

By creating it, you will save finances and get a high-quality capacity for the maintenance of a variety of salts, wines, as well as use for other purposes.

Indeed, in such a capacity, you can not only contain food, but also operate for different purposes on a suburban area.

DIY barrels photo