Each homeowner seeks to protect his plot from prying eyes and thieving hands, and more often a profiled metal sheet is chosen as the main material for the fence.

Among the people, it is better known as a professional sheet or corrugated board and is distinguished by its affordable cost and ease of operation - it is within its power to build a fence from any owner.

Review Content:

Why professional sheet?

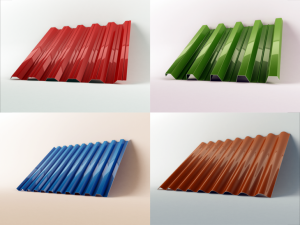

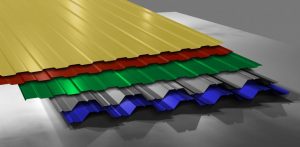

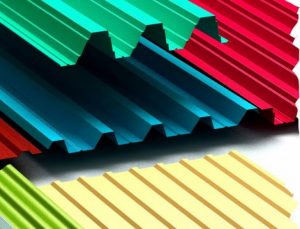

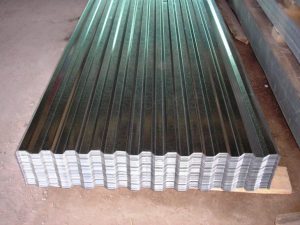

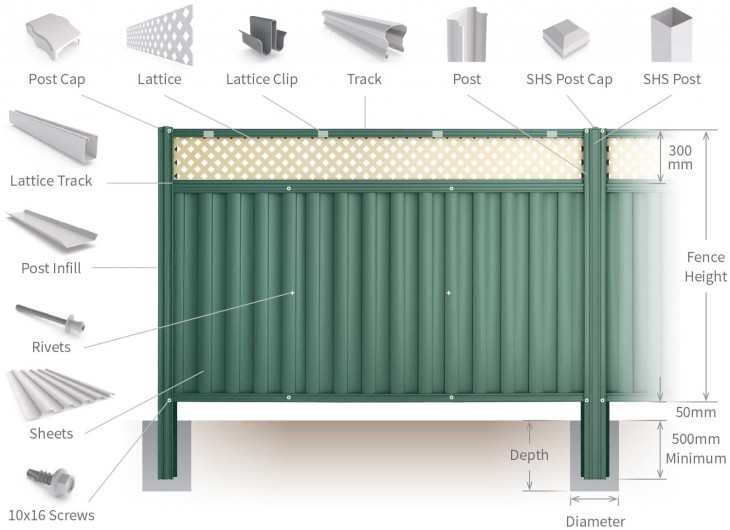

Decking is a steel profiled sheet with zinc or aluminum-zinc anti-corrosion coating. The type of rolled profile and the thickness of the initial sheet determines its functionality and purpose.

So, for the construction of the fence most often choose the most optimal, durable and inexpensive profiled sheets of the "C" or "MP" series.

The fence from a profiled sheet along with cost-effectiveness has several advantages:

- High installation speed;

- The coating is continuous, without cracks or holes;

- Any height of the fence;

- The presence of a sharp protective edge;

- Durability;

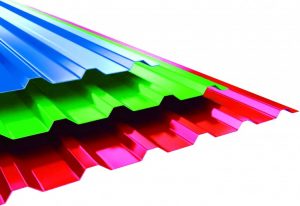

- Aesthetic appearance, a large selection of colors and textures;

- Easy sanitation;

- Muffling street noise.

Materials and Tools

The main advantage of a fence from corrugated board is a limited number of necessary tools and materials, which allows you to install it on your own, without involving a construction team and without hiring special equipment.

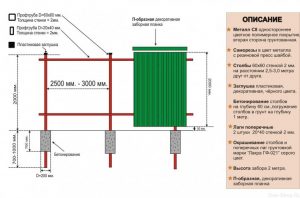

So, the wall or universal corrugated board with a wave height of 18 to 21 mm will become the optimal material for future fencing.

For aesthetics and long service life of the fence, you should choose a coating in advance: economical polyester, resistant to local damage, matte polyester or the most durable pural, plastisol or polyvinyl fluoride.

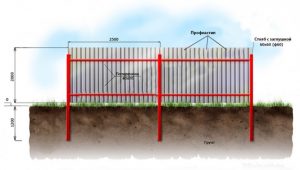

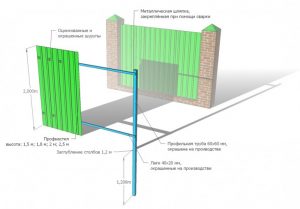

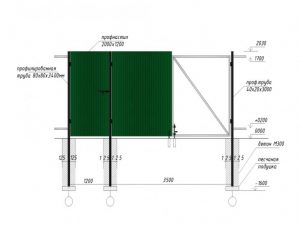

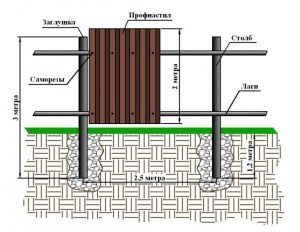

The frame for corrugated board is made of metal pipes of preferably a rectangular profile with a section of 60x60 mm and a wall thickness of 3-5 mm. It is recommended to use jumpers-lags for the strength of the structure.

Concrete mortar, sand and gravel backfill will also be required, and among the tools: mortar shovel, tape measure, welding machine, building level, cord or rope, screws, a drill, a grinding machine and a screwdriver.

We measure and count

First of all, the perimeter of the site is measured, the necessary calculations are made and all the required materials are prepared. The number of profiled sheets is calculated by dividing the perimeter of the fence by the mounting width of the sheet, while the result is rounded up.

The length of the sheet varies depending on the desire of the customer and can reach 3 m. When planning the height of the fence, a mandatory ten-centimeter indent from the ground is taken into account.

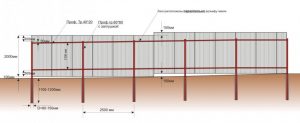

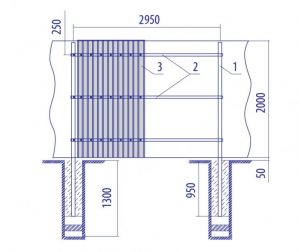

The length of the metal pipe-supports is determined by the sum of the following indicators: the depth of the drilled well and the height of the fence. The number of racks is calculated by dividing the perimeter of the fence by 2-3 m - the recommended distance between the supports.

Fence installation

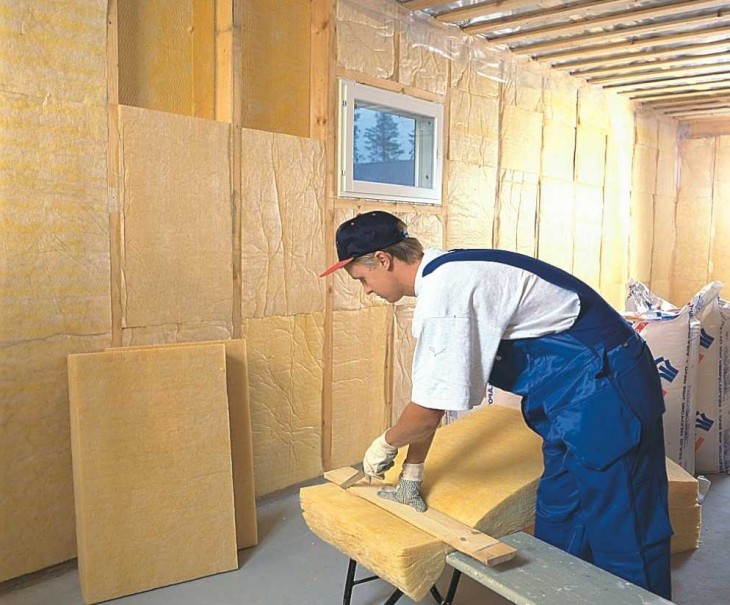

Step-by-step photographs of the construction of a fence from corrugated board show the whole simple algorithm.

The main thing is to correctly calculate the materials, determine the color and texture and choose the appropriate scheme.

The simplest construction scheme for a fence from a profiled sheet does not imply a solid foundation, which makes it the fastest and most affordable.

The following is the procedure:

- For each supporting metal pipe, a well is drilled with a depth of 0.5 to 1.3 m, depending on the characteristics of the soil.

- A concrete mortar is prepared from cement grade M400, sand and fine gravel in a ratio of 1: 2: 4.

- The pipe is leveled according to the building level, fixed with concrete mortar and sprinkled with a mixture of sand and gravel.

- Horizontal lintels are welded to the supports, with an indent of 25-30 cm from each edge of the fence.

- The corrugated board is attached to the cross members with self-tapping screws or other fasteners through each wave.

- Each sheet should be superimposed on the adjacent one wave profile.

Note!

Do it yourself with your own hands to fence each property with a fence from corrugated board for each owner.

The ease and reliability of the design, the minimum required tools and a simple algorithm pleasantly affect the speed, quality of construction and the preservation of the family budget.

DIY do-it-yourself fence photo

Note!

Note!