The most versatile, durable and strong option for laying the floor is a cement screed, which can withstand temperature changes and is resistant to moisture. To achieve an excellent result, it is necessary to strictly observe the technology of work.

Most often, the floor is leveled in the most popular, budgetary and affordable way - with cement and sand. The surface of the cement (as seen in the photo floor screed) is able to repel fats, acids and conducts heat well.

To save budget funds and to be sure of the reliability of the work done, many homeowners are thinking: how to make a floor screed with your own hands?

And this process is not fast, but quite accessible, even to a self-taught master.

Review Content:

What does the screed consist of

This composition is quite simple to knead yourself, in the presence of the following components:

- water (2 parts);

- sand (3 parts);

- cement (1 part).

To make the screed the most dense and reliable, it is worth adding any adhesive substance - a plasticizer to the solution. Adhesive compounds can be purchased ready-made at any hardware store.

Mortar made of cement with sand can be laid on brick, concrete and stone. The solution fits within a maximum thickness of 10 centimeters. If the layer has come out less than 3 centimeters, it is better to use the reinforcement method to avoid cracks.

The main types of cement screed

When screeding the floor in the house, its different types are used, depending on the goal that needs to be achieved in the end:

- Screed with a floating structure with insulating layers.

- Screed that is connected to the surface of the wall and floor.

- Cement screed, independent of surface type.

Preparation for work

Before starting work with a cement screed, it is necessary to correctly prepare the work surface. That is, you need to clean the floor in the room and carefully level it before work.

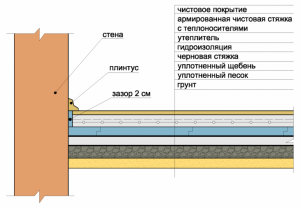

There is a situation when the screed is made directly on the ground. In this case, it must be properly compacted, then pour the composition of bitumen for smooth screed. If this is not done, then cracks can go on the finished surface, since the base will sag over time.

The second step is the installation of beacons, that is, measuring the space of the room with a level and installing icons that correspond to the desired height. This ensures a smooth and even floor.

Beacons help in the future to easily fill a perfectly flat surface. Most often, the columns are placed every 30 centimeters, then beacons - rails are attached to them.

The cement composition should be poured to the highest level, while it is much easier to calculate the required amount of mortar for screeding the apartment, that is, to avoid unnecessary unnecessary costs for materials.

Direct screed work

If the surface is leveled by about 4 centimeters, it is better to make a bonded screed. So filling will connect both the base of the surface and the wall of the room.

It is recommended that you first brush the floor with a brush of metal and slightly moisten it so that the surfaces more reliably adhere to each other.

The composition of the solution itself should be moderately thick and flow freely (without lumps) just above the level of the beacons. This is necessary because with further drying, the fill will settle slightly.

To get rid of excess air (bubbles), after pouring, it is necessary to ram the solution with a vibrating bar.

Note!

At the end of the day, you can remove the beacons, and the traces left by them, carefully primed and wiped with a solution.

There is a disconnected option for leveling the surface. The instruction on how to make this screed is quite simple, but you need to take into account that you will need to provide an even and moisture resistant base. To avoid cracks in the layers, the use of primers and similar substances is not recommended.

Dry floor screed is the fastest way to make the floor as even as possible, which can withstand a fairly large load and will go up to rooms where traffic is increased.

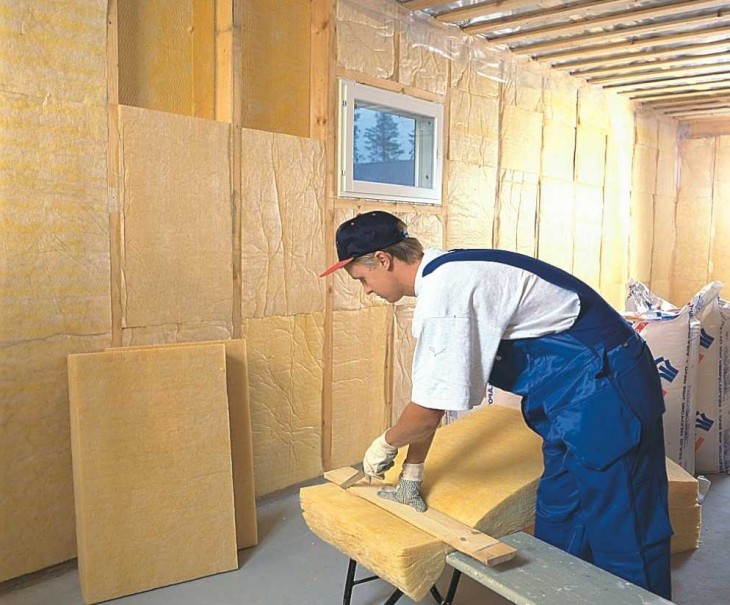

Dry screed can be made of the following materials:

- moisture resistant drywall;

- GVL;

- Chipboard;

- moisture resistant plywood;

- OSB.

Usually, a dry screed is made in height from 3 to 5 centimeters, but, if necessary, it can be higher, but reinforcement with an additional layer of plates will be required.

Note!

You will also need a dry filler - expanded clay, that is, special granules of their calcined clay, which have light weight.

For dry screed, profiles are used that are distributed one and a half meters from each other strictly in parallel, starting from the wall. Then, sheets are laid on a dry screed, starting strictly from the door.

The most traditional, all the same, is a concrete screed, which has been tested by experience and is used for finishing coatings and for installing underfloor heating. If necessary, then in this way it is easily possible to make any desired bias.

With an independent screed, it is important to know that the room should not be heated during the work, as the composition may not dry evenly!

DIY floor screed

Note!