Every year, an increasing number of people prefer to independently make home accessories. After all, often this option is not only economical, but also a unique design.

Specialists strongly encourage this trend, therefore, a huge number of various catalogs are published, which contain not only examples of design design, but also diagrams, drawings.

The most popular product that people prefer to build on their own is a regular chair.

In this article we will consider in more detail how to make a chair from simple materials. We draw your attention to the fact that at the same time you will not need any special skills.

Review Content:

Types of Chairs

Before proceeding directly to the execution of work, we suggest that you familiarize yourself with the existing types of products described in more detail. Indeed, in addition to household chairs, there are other varieties that differ in design.

It is worth noting that most of them are represented by folding furniture, because thanks to it you can use the free space more rationally and economically.

Its cost is not too different from the price of ordinary chairs. Therefore, it is not surprising that modern buyers give preference to just such furniture products.

Folding chairs

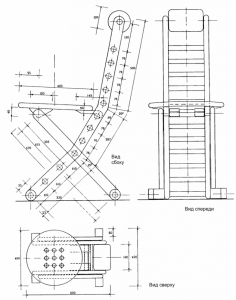

Folding chairs are considered to be the most popular of them, which can have not only a classic and antique design, but also more modern. However, it is worth mentioning that constructing this product yourself is quite difficult.

If you make a mistake with the backrest or if you do not get the shoes of the rear edge of the seat sliding in longitudinal poses, the product will be flimsy.

But if you still decide to make such a chair yourself, we strongly recommend that you use a model with a double seat support. Since this will allow you to evenly distribute the load throughout the product, this way it will become more stable.

Canvas chairs

In second place in popularity are canvas chairs. Unlike folding, they are more rigid. Therefore, they are completely impractical to use for a long sitting.

The best option would be to use canvas picnic chairs. Of course, you can use plywood. However, at the same time its thickness when folded will only increase.

The only way to make the structure “softer” is to complicate it by adding a canvas seat. The complexity of the product is fully paid off with comfort and convenience.

Sometimes lovers to design furniture with their own hands take up the creation of children's chairs. Often they are a regular wooden chair, but slightly modified. Sometimes it is even turned into a ladder chair.

It is worth noting that the number of modifications directly depends on the skill of the person who creates the product. Indeed, for children, what matters most is not the design and the number of modifications, but the strength and reliability of the product.

Everyone knows that sometimes children can break a thing that seemed solid enough, but in fact turned out to be rather flimsy. Therefore, when creating products for children, special attention is paid to fasteners and material.

All about joiner studs

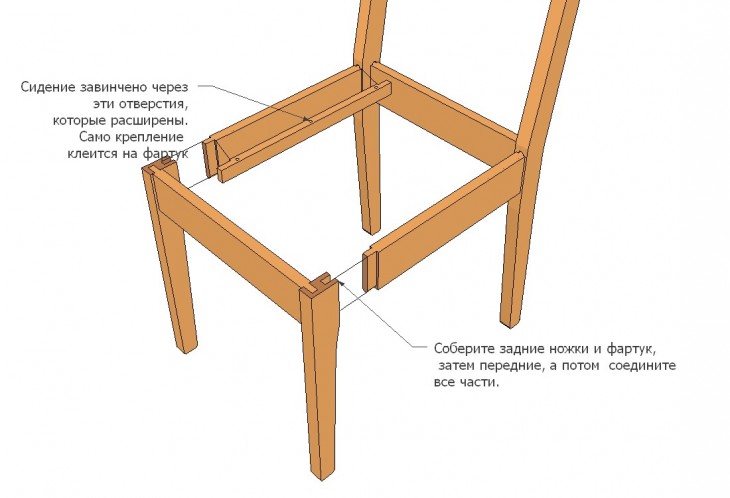

Any person who intends to make a chair on their own needs to understand the thorn groove joinery joints well.Very rarely, joiners use open joints or through studs. Exceptions are only those cases when it is necessary for aesthetic reasons.

Note!

Practically do not use compounds with bolts or self-tapping screws, nails. Of course, all this was once relevant and widely used in workshops. However, progress has done its job. Now joiners use only blind tongue-and-groove joints that are invisible from the outside.

Their assembly is carried out using sizing. Pay attention to the photo of the chair with your own hands, which is presented below. No assembly elements are visible on it and this has a beneficial effect on its presentable appearance.

Sometimes use the method of wedging spikes. Its use is advisable, since no one is engaged in the construction of models with removable legs.

This method belongs to the category of more labor-intensive and requires a lot of time to complete. However, the product ultimately turns out to be strong and durable. This is achieved due to the fact that all the parts with which the joints were created dry out together.

Materials for the manufacture

If you have ever been involved in the manufacture of ordinary stools, you know that for them the most suitable material is coniferous wood or larch. But in the case of chairs, this option is completely unacceptable.

Note!

Coniferous wood is not able to withstand the loads that the chair is exposed to, since it is straight-layered. And this becomes the reason that there is a bevel along the layer.

It is permissible to use only softwood plywood as the basis for the seat.

For chairs made by hand from wood, the most suitable species are: oak, beech, mountain ash, elm and walnut. The listed species of wood are characterized by high strength and density, so they can easily cope with the loads.

You can choose any material from the above, focusing on your financial situation. Since oak and beech are among the most expensive materials, you can successfully use mountain ash or beech. They are not inferior in durability and strength to other types of wood.

And also if you want to save a little more, we recommend that you buy not an sawn tree, but an array. It will cost much less, and you can cut it yourself using a circular saw or grinder.

Note!

Preparatory work, which are mandatory, is also not particularly difficult. Therefore, think in advance where it will be convenient for you to conduct them. It can be either a storage room, a garage, or a room in the house.

You will need to purchase a water-polymer emulsion or any other harmless biocinide in advance. With their help you will carry out processing and impregnation of a tree. This procedure will improve the quality of the material. The procedure should be carried out in a dry room.

Which backrest to choose?

Often, those who are engaged in the independent manufacture of chairs have problems with choosing the right back for the product. They come in 3 types: whole-hard, with typeset rigidity and soft.

If you want to make a simple chair back with your own hands, then the most suitable option would be a solid one. It is a curved bar, which is cut in the same way as curved legs. It is necessary to collect it with the help of spikes.

In no case do not use screws, because they look pretty rough and can ruin the appearance of the product.

To design a soft back you will need: a straight bar and an intermediate support. As its basis, plywood with a thickness of 4 or 6 mm should be used. Sheathing backs can be foam or felt.

If you plan to use foam rubber as a lining, then do not take it too thick. In this case, you will have a thickness of 7 mm. Your soft stuffing should not reach the edges, so you need to indent from them about 20 mm. Some craftsmen even use decorative cladding.

However, experts are sure that it can be successfully replaced with covers. After all, the covers for chairs made by yourself do look pretty neat and beautiful. In addition, it will be much easier to sew them than to independently perform decorative lining.

DIY chair photo