Rabitsa is very popular in the construction business and in landscape design companies.

For its own production you need to have certain equipment. I want to tell you more about the nuances of mesh manufacturing.

Review Content:

General information

The chain-link is a component of some structures that are widely used in the manufacture of enclosing elements, fences, dog enclosures, sift sand with it and construct a framework for climbing plants.

The name of this material comes from the name of the famous inventor K. Rabits. To obtain a mesh, simple machine tool equipment is used, with which the spirals are mutually screwed, as well as high-tech machines equipped with automation, which produce a huge amount of production in the form of a chain-link grid in a short period of time.

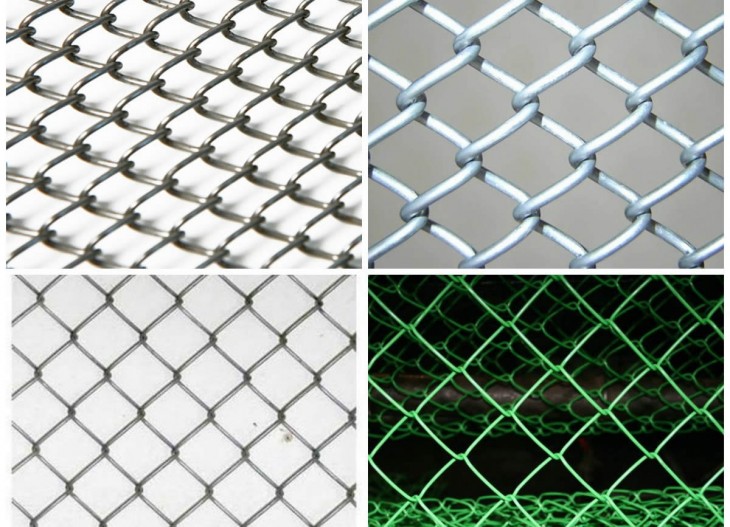

The main material from which the mesh is made is low-carbon steel, galvanized and polymerized wire, in rare cases stainless steel is used.

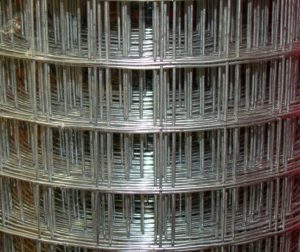

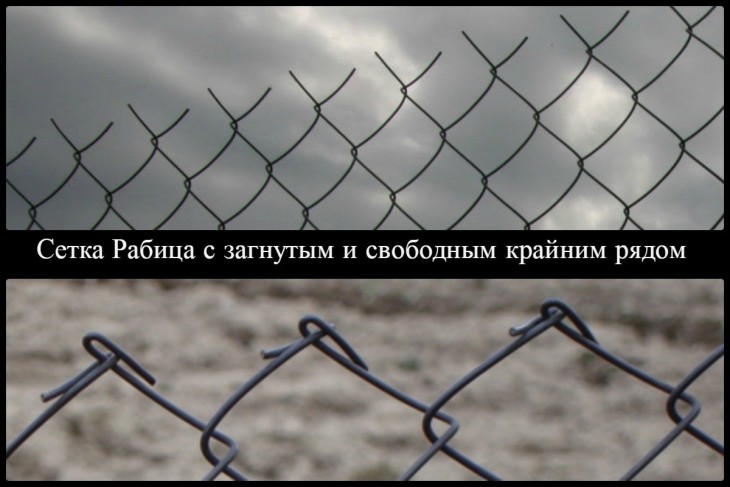

According to the shape of the cells, a grid is distinguished: diamond-shaped and square. This is shown in the photo of the mesh netting.

In the construction market, the grid is sold in rolls with a height of 1.5 m and a length of almost 10.0 m. Sometimes manufacturers can independently change the parameters of the rolls. For hand-made nets, the edges do not curl.

For transportation of the chain-link it is necessary to wrap the edges with synthetic material or polyethylene.

The mesh is mainly used for street needs, i.e. outdoors and exposed to climatic conditions. So that the mesh does not rust after the first rain, it is treated in the form of painting, galvanizing or polymerization.

Galvanizing is the most famous method. For this, galvanized steel with a high zinc content is used. Typically, zinc is applied to the surface of the wire by hot dip galvanizing.

The term of use of such a wire will be 20-25 years. And the service life of galvanized wire by the electrolyte method will be about 3 years and no more.

To use the chain-link near various bodies of water (rivers, seas, lakes, etc.), it must be made of high quality polymerized steel to protect it from rust. Poor quality coating will soon become dull and cracked.

When choosing a polymer-coated mesh, choose expensive options and reliable manufacturers that guarantee quality and long-term durability.

Do not forget to check the surface of the spirals for cracks; their absence will confirm the high quality of the product. If cracks are noticeable, then the mesh will last less than a year as a result of rust from moisture penetrating through them. Its strength depends on the format of the cells and the thickness of the wire.

Manufacturing equipment

For home production of mesh, equipment can be made by yourself, having initial locksmith knowledge and skills.

The chain-link, in comparison with other similar products, has some advantages. To make it, you do not need to have spot welding and an electric drive device.

For the manufacture of mesh in large volumes, you can purchase an assembled industrial machine, and for a small volume, equipment of our own production is enough.

Note!

In the manufacture of the fixtures on their own, it is necessary: a piece of pipe, plates, metal pieces, bearings, rollers, grinder, metal corners, rope, crayon, file and sandpaper.

The chain-link mesh frame is formed by connecting a flat-shaped wire. The main circumstance is the manufacture of a zigzag snake using mechanisms that perform tension and winding.

Tension helps to avoid excessively strong twisting; winding makes the structure stronger. A spiral in the form of a screw is reluctantly screwed into the main blade. The wire tension must be constantly adjusted.

When bending, the wire changes shape and begins to rub against the machine, in order to avoid this, it is necessary to lubricate it with used oil.

The winding device has its constant dimensions, on which the type and diameter of the cell depends. When creating the shape of the turns, the line should be smoothly screwed into the main canvas of the netting net. Then, the excess part is removed.

Note!

The chain link weaving device consists of a winding unit that has a screw, a metal plate and a knife. These details set the shape of the spiral and wear out quickly, so they must be of high quality and durable.

A spinning knife forms coils of a certain format. The screw sets a certain distance from coil to coil. The result is a grid with equal cells.

The winding plate looks like a strip of metal with a hole on the edge, with which it is fixed on the handle. Using a stiffer wire, the metal strip is twisted 60 degrees with a screw. The stiffer the wire, the higher the degree of twist angle.

The auger is a red-hot steel pipe having a cut in the form of a spiral over the entire surface. A locksmith will help to make such a detail or purchase it on the market, do not make it yourself.

How to make a grid

Position all components so that it is easy to twist the handle and guide the wire evenly. Make sure that the wire is not tangled. To do this, place a bucket in the middle, turned upside down, and place the edge of the wire in a metal pipe and weight it in another way. This will help avoid banding.

Pull the end of the wire through the rollers and change the gap between them with a screw. After, insert the wire into the winding mechanism and twist to a certain cell size. The line at the output should be even.

Note!

Remember to adjust the tension. If the wire looks perfect, twist on until you get the required volume of the product. The installed controller will help determine the number of turns and make the process itself easier.

Having improved the device with an electric motor, it will not be necessary to twist the handle manually. Such a machine is suitable for home use and a small volume of products.

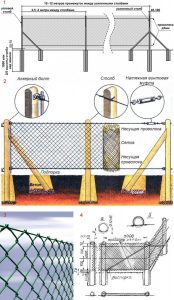

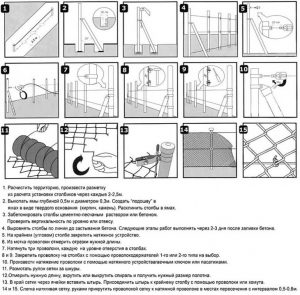

Installing a netting netting is much more profitable than building a wooden fence, which is necessary from time to time to paint and repair, especially since the fence from the net can also be made with your own hands.

DIY do-it-yourself grid photo