Self-made floors in the house will help to save a lot of money, as well as to make sure of their reliability and quality by personal experience.

If you have the required materials, tools and knowledge, then every man can professionally install flooring.

Review Content:

Determine the design

Features of the building, living conditions dictate their requirements for the construction of the main floor, each type of which has its advantages and disadvantages:

A single floor is attractive due to its simplicity, economy and fast masonry technology, but this affects its functionality: this coating is not designed for year-round use and is used only in summer houses, terraces, porches, arbors and summer cottages.

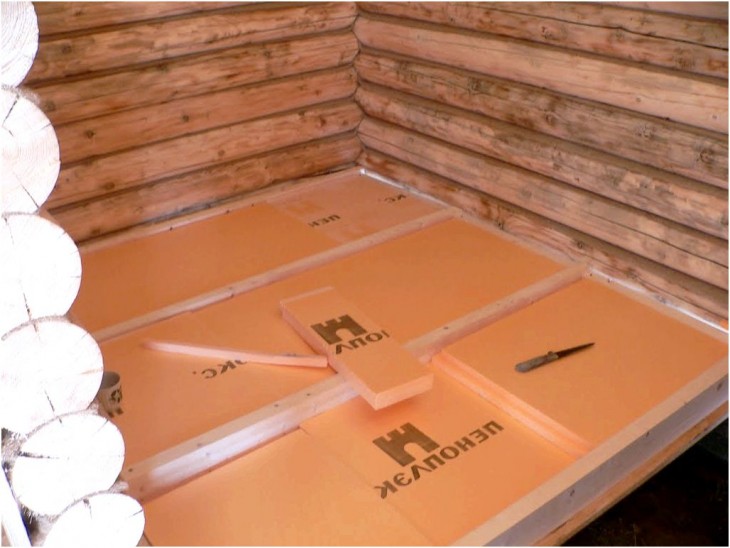

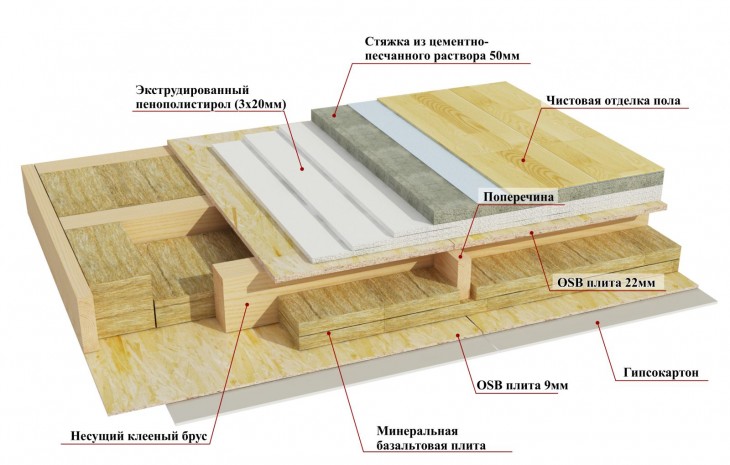

The double floor provides heat preservation in the house due to several layers: rough coating (not edged board), fine finish (grooved floorboard), waterproofing materials (bitumen, polypropylene, fiberglass, polyester), floor logs and insulation (sawdust, expanded clay).

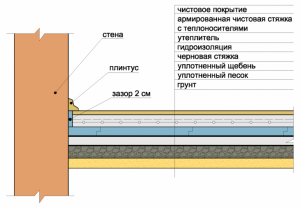

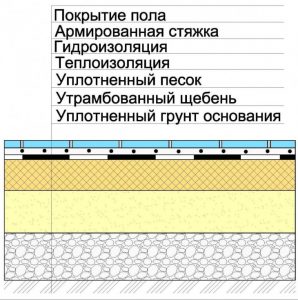

Concrete flooring requires serious preparatory work, laying waterproofing and pouring cement, which as a result gives a strong coating, ready for decoration with any decorative building materials.

Pour concrete floor

Most often, a concrete floor is used as the main coating, which is more reliable and durable.

To make a concrete floor in the house with your own hands, you need to follow the universal algorithm:

- The necessary marking is made around the entire perimeter of the room, after which the entire surface is covered with cleaned gravel and thoroughly compacted.

- A layer of sand is laid and trampled on top of the gravel.

- Around the perimeter of the future floor there is a waterproofing polyethylene film.

- Concrete mortar is prepared from cement (M-300), sand and water, to which plasticizers are added if possible.

- Next, the floor screed is performed: levels are set, cement mortar is poured and leveled by the rule in the direction from the wall to the exit.

- If the height of the screed exceeds 5 cm, then reinforcing elements are used: pipes, nets, spare parts.

- After the concrete has hardened, beacon levels are removed, and the remaining voids are filled with mortar.

- The finished floor is covered with polyethylene and dried for at least 1 month.

- Regularly, concrete is recommended to be opened, moistened with clean water and again covered with a film, which will ensure the integrity and strength of the floor.

Concrete

Concrete coating serves as the basis of the floor and requires a decorative coating, which is most often used as parquet, laminate, linoleum, carpet or ceramic tile.

The combination of several types of flooring is popular: laying tiles in the bath and kitchen, linoleum in the hallway or corridors, laminate in the living room and dining room, and carpet in the bedrooms and the children's room.

The color and texture of the coating is selected depending on personal tastes, the interior of the room and its functionality.

For example, in private homes and landscaped cottages, it is more appropriate to choose natural ornaments, wood textures and shades of natural stone.

Wooden floor

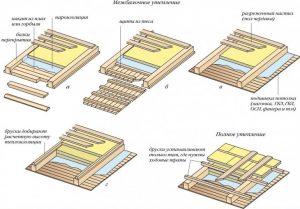

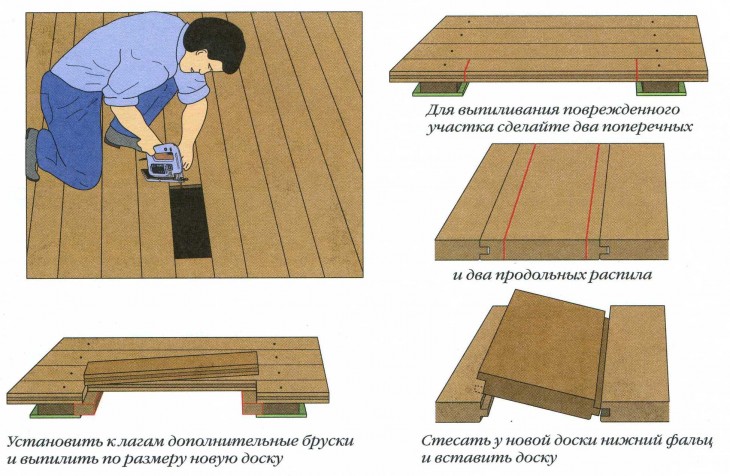

In private homes, it is better to make the floor of wood, which is characterized by easy installation, repair, long life, "natural" appearance and heat preservation.

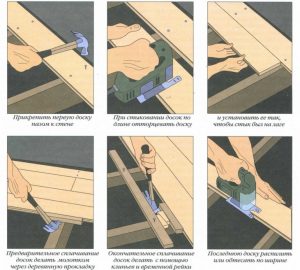

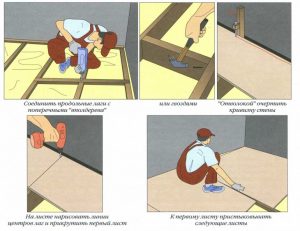

To correctly install such a floor in the house, it is better to familiarize yourself with step-by-step photos of the construction of wooden flooring in advance and follow the general recommendations:

- You need to choose well-dried and treated with antiseptic and flame retardant boards from pine, larch, fir, cedar;

- First, the locations for the pillars are determined;

- Along the perimeter of the room, the soil layer is removed and replaced by gravel-sand;

- As a waterproofing material, it is better to use roofing material;

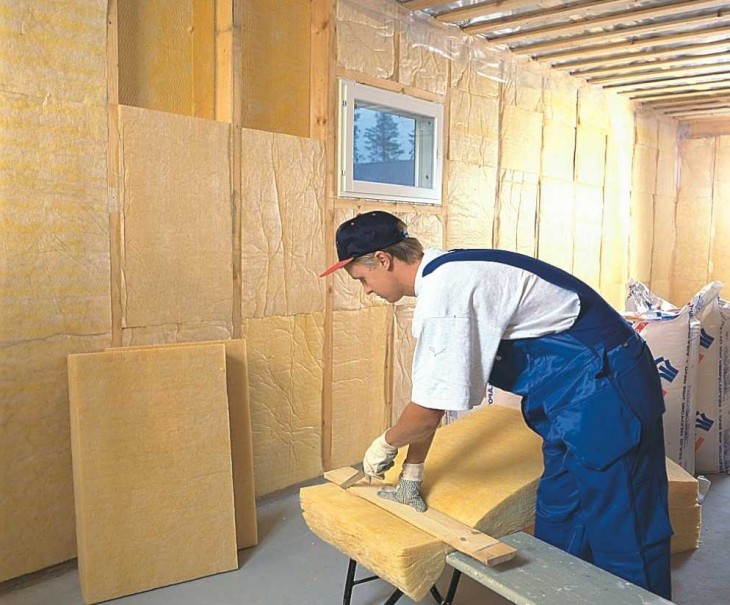

- It is possible to insulate the floor in a private house by laying mineral wool;

- A target of 1.5 cm is left between the rough flooring and the wall;

- For a final coating it is advisable to use tongue-and-groove boards or plywood sheets;

- After assembly, the wooden floors are varnished.

To make in a house or apartment a high-quality, durable and warm floor is within the power of any person, especially savvy in the construction industry.

The main thing is to correctly calculate the amount of materials and follow the attached instructions.

Photo of the floors in the house with your own hands

Note!

Note!

Note!

Do-it-yourself vase - stylish decoration and creation of designer models (photo and video)

Crafts from beads - 72 photos of a detailed description of the process of weaving beautiful things

Crafts from plasticine - the best news of DIY crafts for children (150 photos + instructions)

Do-it-yourself fence from corrugated board: 57 photos, schemes and construction plan