Traditional brick ovens are increasingly preferred to steel and cast-iron models. Large heat dissipation, a rare fire chamber and a non-burning case, the preservation of humidity in the house - these indisputable advantages make it in demand in our time.

Among the many “pluses” there is a simple masonry, which allows each owner to build a brick oven with his own hands.

Review Content:

Brick stoves in the home

The functionality of a brick oven is not limited only to heating the house in cold weather or cooking, as in everyday life it can serve for smoking meat and fish, maintaining the heat in the bathhouse.

There are also narrowly targeted aggregates used for smelting metals, firing ceramics or clay, heating, hardening and cementing metal workpieces.

The most popular types of stoves are:

A Dutch or channel sequential furnace has a simple and compact design, but a lower efficiency (only 40%).

The Swedish stove will be optimal for domestic use, heating and cooking, among which there are 60% efficiency, a special oven and uniform heating of the room due to its high design. However, only a professional will be able to build such a stove for the house on their own.

Difficult in masonry and serving only for heating purposes, the bell-type furnace has an efficiency of more than 71%, but requires very careful maintenance and frequent heating.

The Russian stove has the highest useful coefficient at the level of 80%, comparing favorably with both its external originality and the stove bench, and making it possible to cook Russian national firebox dishes. Such an oven can be folded on its own, if not deviate from the scheme.

Standard furnace design

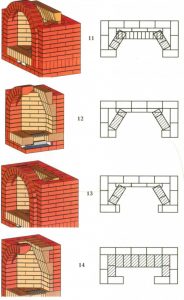

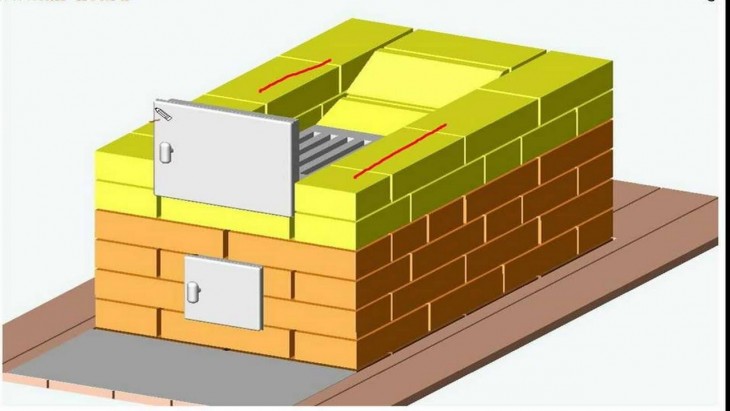

Having carefully studied the photo of brick ovens, you can understand the general structure of their design:

- The foundation is monolithic or laid out of brick, reinforced concrete blocks, protects the floor from heating and fire;

- Firebox - a chamber intended for combustion of fuel and closed by a door;

- The grate at the bottom of the firebox is called grate and serves to penetrate air into the fuel;

- The resulting ash is blown into the ash pan or blown through the grate;

- The channels created inside the furnace are necessary for the passage of hot air through them, resulting from combustion in the furnace and going outside through the chimney.

Necessary materials

During the construction of the kiln at different stages, several types of bricks (building, kiln and chamotte) and mortars (cement-sand and clay) will be involved.

For smooth laying of bricks and applying mortar to them, 3-4 different types of trowels, a pickaxe, a rope, a mallet, a plumb line, a building level, a rule, a square, a squeegee, a meter, a tape measure, an embroidery and a mortar shovel will also be required.

General recommendations for masonry

Before proceeding with the construction of the furnace, it is necessary to determine its location, type of structure, purpose and size.

The right recommendations and calculations will help the following recommendations:

- A kiln, for the laying of which more than 500 bricks are required, a foundation is needed that protrudes more than 5 cm on each side.

- The chimney must not come into contact with attic beams or other wooden roof elements.

- When buying a brick, you should pay attention to the quality of the burn, the integrity and strength of the material.

- Before masonry, the brick is soaked in the solution for several minutes. 5.The seams between the bricks in the fuel combustion chamber and the ash pan are up to 10 cm wide, in other areas at least 3 mm.

- Each new row begins with corner bricks, the evenness of the masonry of which is checked by level or ropes stretched around the perimeter.

- To avoid cracks on the surface of the furnace, dressings are made during masonry.

- Between the hob and the brick wall, it is recommended to leave a hole of several millimeters.

- Tile or ceramic decoration will harmoniously fit the stove into the interior.

Note for beginners

In the absence of sufficient construction experience, it is recommended not to step back from the masonry layout of the furnace.

It is also necessary to adhere to some tips for beginners:

Note!

- Initially, a number of bricks are laid out without mortar, leveled and then shifted.

- The ash pan door is installed as standard on the 3rd row.

- Each brick is thoroughly cleaned of dust, sand or stones; if brick laying is unsuccessful, the solution is removed and applied again.

The ability to lay a stove will help not only to organize high-quality heating in the house, but also to build a wood-burning street stove or an elegant fireplace in the living room.

The basic rule is not to deviate from the drawing and do everything smoothly and firmly.

DIY brick oven photo

Note!

Note!

DIY sofa - 73 photos of a life hack to create a stylish and comfortable sofa

Crafts from leaves - 100 photos of the best ideas for fakes from dry autumn leaves

DIY sofa - 73 photos of a life hack to create a stylish and comfortable sofa

DIY autumn crafts - 200 photos of the best options + simple instructions with a description