As a rule, planting is done in the spring, but you need to take care of the conditions, in particular, we are talking about protection from low temperatures. Especially when it comes to vegetables.

Greenhouses and greenhouses do an excellent job of this task. How to make it from almost improvised materials and see below.

Review Content:

- How is a greenhouse different from a greenhouse?

- What are the greenhouses?

- Material selection

- Glass

- Film

- Polycarbonate

- What to use for the manufacture of a frame for a greenhouse

- Wood frame

- Execution sequence

- Roof

- Doorway

- The use of metal pipes

- Covering the greenhouse

- Film

- Polycarbonate

- Ventilation

- DIY greenhouse photo

How is a greenhouse different from a greenhouse?

Before delving into the question of how to make a greenhouse, let's decide what the difference between a greenhouse and a greenhouse is:

- The greenhouse is used for growing seedlings and further planting in open beds, in the greenhouse, plants can be year-round;

- The necessary temperature level in the greenhouse is maintained due to the presence of compost or manure in the soil, while in the greenhouse there is an additional, third-party source of heating;

- It is possible to grow trees in the greenhouse, but this will not work in the greenhouse.

What are the greenhouses?

The greenhouse can be stationary or portable type (photo of the greenhouse in the country is presented below).

A stationary greenhouse can have all kinds of shapes, the most common model is a butterfly (it got its name due to doors opening on both sides).

Wearable more often in the form of a tunnel. The main material in both cases is a polymer film.

From all this it follows that making a greenhouse with your own hands is quite possible, this is the same creative process as growing cucumbers, tomatoes, etc.

Material selection

Before considering how to make a greenhouse with your own hands, we will deal with the issue of choosing a material.

When choosing a material, it must be borne in mind that it must meet the following requirements:

- Good light transmission;

- Resistance to various kinds of deformations, with strong gusts of wind, for example;

- Easy installation and assembly of the entire structure;

- Durability.

As for the materials used, the cheapest, and most importantly practical, is the film, and here are its types:

- polyethylene;

- stabilized film;

- polyvinyl chloride.

Cover materials include:

- agril;

- lutrasil.

In order to finally determine and understand which material is preferable, it is necessary to compare them, and consider the pros and cons of each.

Glass

The advantages of glass include: transmits approximately 94% of the light, serves for a long time, retains heat.

By cons: heats up very much in the summer, a heavy load on the main frame.

Film

The advantages of this material include: low cost, low weight, no foundation needed.

Note!

By cons: fragility, difficult to wash.

Polycarbonate

Pros: good light transmission, high level of thermal insulation, light and durable.

What to use for the manufacture of a frame for a greenhouse

The frame is a kind of basis of the greenhouse, most often it is made of wood or plastic, less often of metal pipes.

Wood frame

The main plus is its environmental friendliness. It is also worth noting that it is very simple in terms of installation.

For installation, you will need the following tools: a hammer, a screwdriver, a saw, nails, rubber as a sealing element, wooden bars, a ruler.

Note!

It is advisable to cover the wooden elements of the future design with drying oil before the installation process.

Execution sequence

First of all, a timber is attached to the mortgage fastening, it will further become the base. Then the main beam is placed around the perimeter of the foundation, and temporarily everything is fastened with nails.

Side and corner beams are fastened diagonally with a beam. The door frame is installed to the side pillars. The cornice is mounted at the top of the side and corner beams.

Roof

In the area of the points where the vertical beams are fixed, you need to bring out a beam, the length of which is 2 m. Roofing beams must be fixed at an angle equal to 30 degrees, they are connected to each other by a beam. In the area of the end points, they must be supported by vertical guides.

The final fixing of the roof frame is done with the help of corners and strips on the screws.

Note!

Doorway

The door frame is attached first. Do not forget the middle and upper part of the opening is fixed with special stiffeners.

The use of metal pipes

A greenhouse, as mentioned above, can be made from metal pipes, and also with your own hands. This design is more wear resistant.

You will need: a welding machine, a hammer, a grinder, a special nozzle for working with metal (disk).

The pipe is divided into two identical parts. On the edges of the base pipe, tees are welded, crosses are welded every half meter. The cut off elements need to be welded to crosspieces.

On an arch for fastening of a rack of a door special tees fasten.

Covering the greenhouse

After the frame is ready, you can begin to cover.

Film

The easiest material to use is film. It is necessary to cover the entire structure, leaving a margin of 15 cm, and then cut it off.

Polycarbonate

The front side of the polycarbonate, the one where the picture is shown. First you need to cut the sheets. Seal the sections from above with a sealing tape, perforated below.

First, polycarbonate is mounted on top, then already on the sides. Mounted on the frame with a special profile, as well as rubber gaskets.

At the end, a sealant and door hardware are installed.

Ventilation

In greenhouses, in order to create ventilation (ventilation), you just need to open the doors, only do this preferably in warm weather.

A greenhouse is an indispensable thing for a gardener who is going to collect a large crop of tomatoes, cucumbers and other vegetables in the future, coming up wisely to the design and following all the instructions, everything will surely work out.

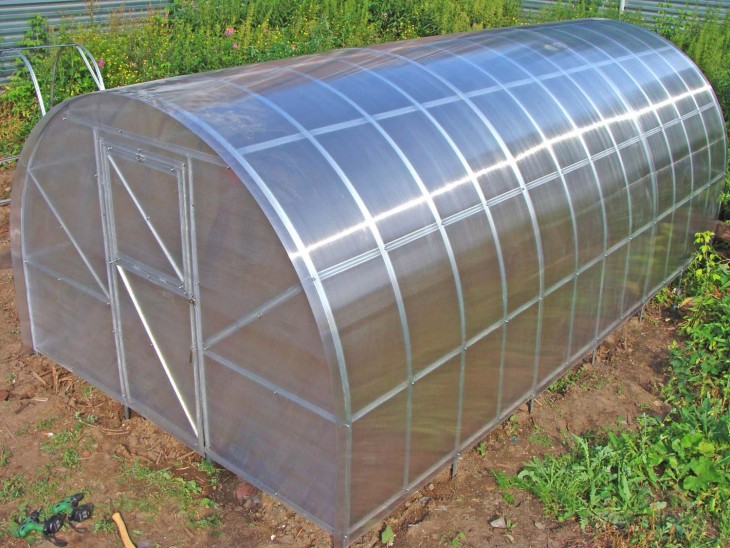

DIY greenhouse photo