A broken bed is not a reason to run to the store, especially if the house has parallel bars and screws. With the help of simple materials, everyone can make a double bed with their own hands, and personal preferences and wishes will serve as a guide.

The original bed will exactly match the necessary size, height and weight of the owner, and also fit perfectly into the overall interior design.

Review Content:

At the heart of a tree

The bed frame can be made of iron or wood. And if the first option requires special skills in working with iron and hard-to-reach materials in the form of profile pipes, then every economic person will have parallel bars along with the ability to handle a screwdriver and tighten self-tapping screws.

The assembly of such furniture will take no more than 10 days, and only safe and high-quality materials are used: self-tapping screws, sheet plywood, MDF panel, metal corners, PVA glue, boards and pins.

General recommendations

Properly and quickly assemble a strong and stable bed will help some recommendations:

- It is better to give preference to an even beam on glued pine about 200 cm long;

- The dimensions of the future frame are recommended to correlate with a pre-purchased mattress;

- For boxes complementing the design, sheets of chipboard should be purchased;

- Self-tapping screws and other fasteners are bought with a margin;

- On the bases of the folds of the metal corners there should be no roughness indicating low quality.

Getting started assembly

Once everything you need is ready, you can start assembling the bed. The algorithm will be the following scheme for the manufacture of the components of the bed with your own hands.

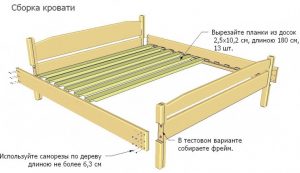

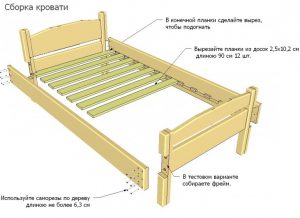

Frame and stiffeners

The first step is to make a rectangular frame, each side of which consists of three beams fastened in height. Further, the following manipulations are necessary:

- A beam measuring 4x5 cm is sawn into 4 parts: two by 16 cm and two by 21 cm, which are laid out on the floor together with the frame and are fixed with PVA furniture glue.

- The second layer parallel to the parallel bars, firmly fixed with screws on both sides. Periodically it is necessary to check the evenness of the structure with a tape measure or rope. Protruding excess glue must be immediately wiped with a cloth, preventing it from drying out.

- At least 3 cm thick slats are taken for the base of the bed. To strengthen the load-carrying capacity in the center, a "stiffener" is made, passing along the bed and having two supports.

Feet and legs

Four pillars are needed in every corner. Each leg is made of two sections of a 4x5 cm timber, while gluing their PVA seams, connecting them together with self-tapping screws and attaching to the main frame. After which the product is turned over and mounted on the legs.

The basis for the mattress

Bars for support are provided by the drawing of the bed and, depending on the suitable option, come in different thicknesses, heights and locations. Most often, they are equal to the inner length of the frame and are mounted at the level of the second row.

To create an optimal orthopedic base, the rails are fixed at a distance of about 20 mm, fixing them at the edges and in the center for two self-tapping screws in each place. After the future bed is left to allow the glue to dry.

Sanding and painting

Final processing consists in polishing the entire surface, thoroughly washing the product. Before painting, a protective wood primer is applied to the perimeter of the structure, and the bed is painted with high-quality wear-resistant varnish in 3-4 layers.

We upgrade standards

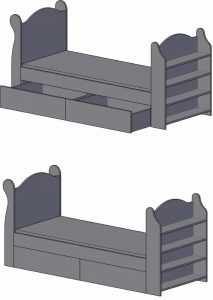

One bed is good, and a children's bed and a bunk bed are even better, especially since making it with your own hands is as simple as a standard model.

Choosing a suitable scheme, you can experiment with the dimensions and design: make two beds, put a desk, sofa or lockers on the ground floor.

Experienced and motivated craftsmen will be interested in another modern and functional model - a podium bed. In this case, you will have to accurately measure all the sizes of the room and prepare the lumber in strict accordance with the required area.

Mandatory drawers at the bottom of the bed and hidden side panels.

If your soul and body require a new bed, then do not rush to run to the store. Making this piece of furniture with your own hands is simple and quick, and the final result will directly depend on individual wishes, taste and area.

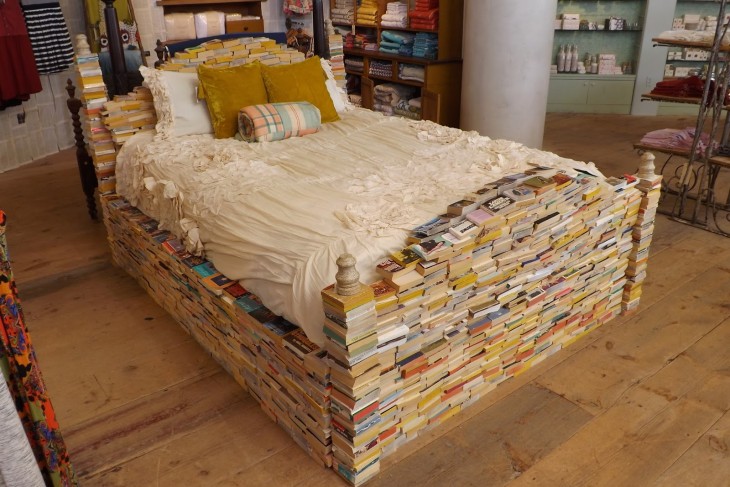

DIY bed photo

Note!

Note!