Architects and designers often use forged elements in their work. Openwork metal grilles covering the fireplaces, or beautiful balusters on the stairs look elegant and noble.

If you know how to perform forging and learn this craft, you can create original products yourself.

This lesson is suitable for everyone who likes to do physical work and who is ready to get acquainted with the technology and the features of choosing metal.

Review Content:

What you need to know about forging?

Forging is a processing process for a special workpiece. Its purpose is to give the metal the required dimensions with shape. Distinguish between hot forging and cold.

The master needs to get acquainted with both varieties in order to know the advantages and disadvantages of each.

Hot forging method

In the hot method, the metal preform is heated very much. As a result, the metal becomes ductile. Hot forging gives the workpiece the desired dimensions and the desired shape. A variety of work options are available to the wizard.

There are also disadvantages to heating a metal billet. First of all, it is necessary to equip a special room. You will need to buy a blacksmith forge, for which you have to buy fuel.

It is necessary to comply with fire safety rules, it is important that the master knows how to work with fire.

Having an idea of the temperature conditions used in the forging process, you can easily select the desired type of forging.

Cold forging method

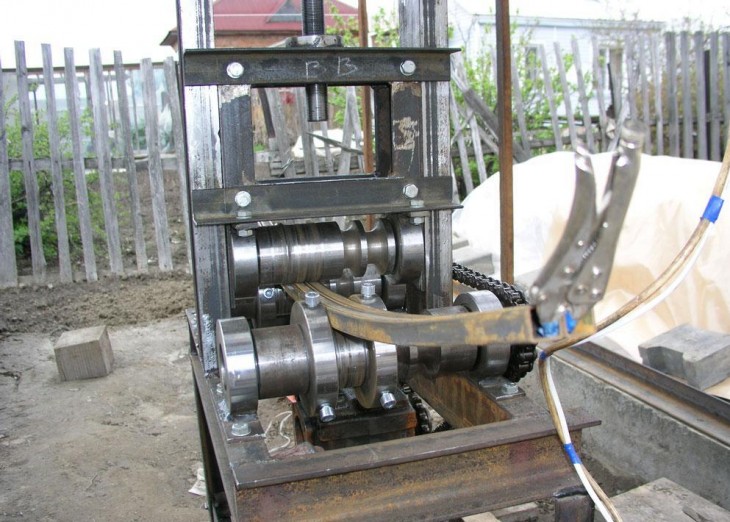

Cold forging is a labor-intensive process. In order to achieve the shape that is required from a metal workpiece, it is bent, crimped and welded. The execution technique is slightly simpler compared to the hot method.

A workshop does not require a lot of space, and for its arrangement it will not be necessary to purchase a special horn, just buy a forging machine.

The manufacturing process of the product involves working with prefabricated semi-finished products. If a mistake was made, then it is impossible to fix it.

Choose metal

For hand forging, metals with certain properties are suitable. The more ductile the metal, the easier it is to change its shape. However, ductility is inextricably linked to strength.

An increase in the indicator of one characteristic inevitably entails a decrease in the other. When buying a blank, the master must know exactly what its composition is.

The craftsman forges decorative elements from copper, steel, duralumin or brass. In addition, alloys may also be used. Information on metals that are easy to forge can be found in the Marochnik of Steel and Alloys.

What kind of tools do you need for forging?

Inventory varies depending on the forging method. Blacksmith forge with anvil, mallets with ticks will be needed for hot forging.

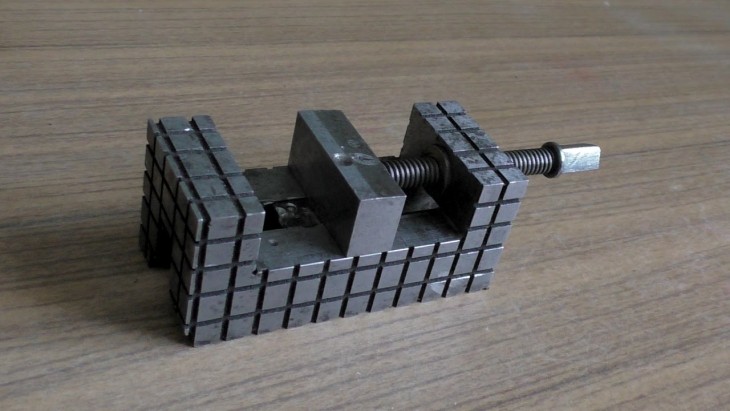

For the cold method, you need the Gnutik tool, which allows you to bend the workpiece at an angle, and the Snail machine for forging, which you can do yourself. The last machine allows you to create decorative elements with a shape in the form of a spiral.

Note!

In addition to the basic tools for the cold method, “Flashlight”, “Wave”, “Twister”, a machine for rings and others can also be used.

The modern market offers industrial machines designed to perform technological operations.In the forging photo you can see the product made on the Master 2 machine from MAH.

Hand forging

In order for the workpiece to acquire the desired shape, the master must apply various techniques and methods in his work. You will need to purchase various tools and master various technologies.

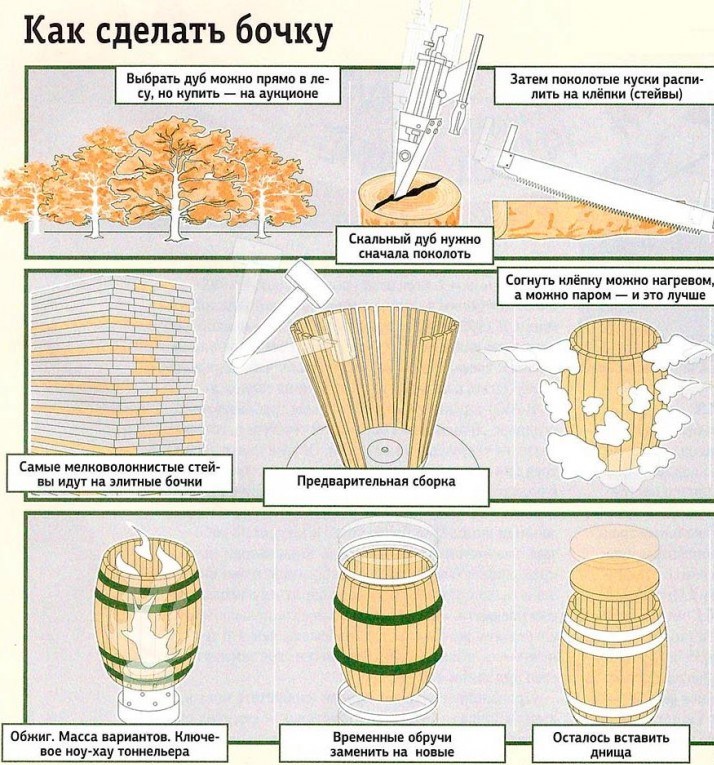

The cold forging method does not require special efforts from the master. The following stages are distinguished in the work:

- creating a drawing or sketching a decorative element;

- procurement of blanks;

- forging process.

Today, a drawing can be done using a computer program on your own or ordered by professionals. The project will allow, before starting work, to calculate how much metal blanks need to be purchased.

Note!

The main forged elements are represented by the following groups:

- Paws. The end of the metal rod is given a certain shape.

- Curls. The ends of the rod can be bent in one or two directions.

- Rings. Decor elements are made of rods with a square or round cross section.

- Torsion. It is characterized by helical axis twisting.

3 generally accepted technologies are used: drawing, bending and twisting.

- The hood allows you to increase the length of the metal workpiece, reducing the value of its cross section.

- Bending makes it possible to bend any part of the workpiece at an angle.

- Twisting - a technology in which the workpiece is twisted along the axis. For twisting, the Twister machine is used.

All elements come together and are fixed by welding. These operations are performed on a special table. Homemade cold forging does not require special skills.

DIY forging photo

Note!