What could be tastier than homemade smoked meats? Many masters are interested in the description of the principle of creating homemade products useful in the household.

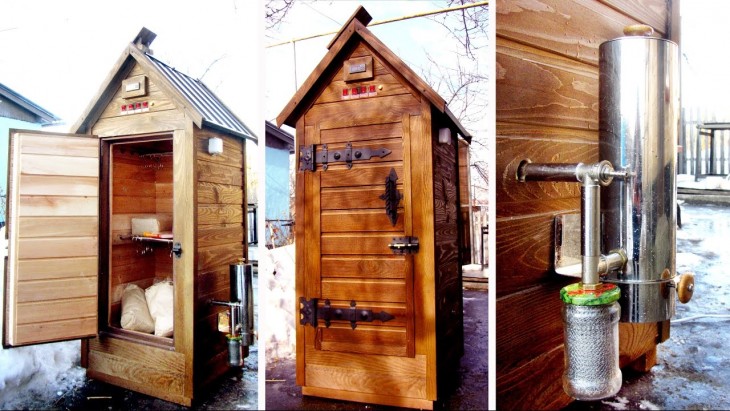

Finished products are captured in the photo, cold smoked smokehouses can be made by yourself. Home-made products are a welcome treat.

Review Content:

Self-made construction

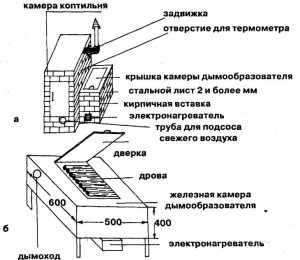

Cold smoking is the processing of food using smoke, which has a temperature of 32 degrees. The process should be organized correctly, so the master will need to figure out how to make a cold smoked smokehouse correctly. It is important not to make a mistake with the construction scheme.

Hot smoke must be cold. To do this, use the tunnel, which connects the furnace to the compartment where the products are placed. The length of the tunnel can vary between 2-7 m. This distance is taken into account to calculate the length of the chimney.

If the furnace is located at a distance of more than 7 m from the smokehouse, problems with traction, as a rule, cannot be avoided.

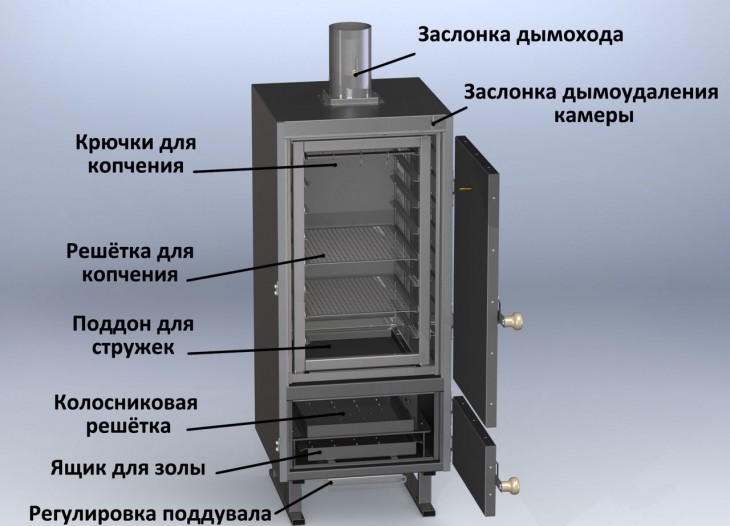

How does the device work?

The principle of operation of a homemade smokehouse can be represented as follows. Food processing can last from 3 days. The process can continue for several weeks.

The main thing is to ensure that the smoking process occurs evenly. In the smoking chamber, do not mix different types of food.

You need to cook food in one go. It is important to sort the products by size.

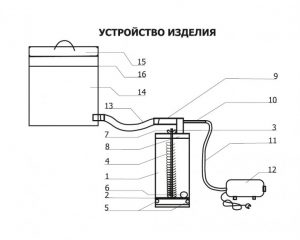

Read more about the design of the smokehouse

To make a furnace, you need to dig a trench with dimensions of 50x50. These values may be larger. Often the width with depth of the pit is made meter.

The bottom of the furnace can be made of brick, and then cover it with a tin sheet. There is no need to prepare a cement mortar. It is enough to compact bricks close to each other. The sides are also finished with bricks. Here, for masonry, you need a clay solution.

Creating a drawing of a cold smoked smokehouse, it is required to take into account both the remoteness of individual parts of the structure and the dimensions of the materials.

Under a chimney with a diameter of 25 cm, a trench is specially excavated. From above it needs to be closed with a sheet of iron. To prevent smoke from seeping in, the sheet material is covered with earth.

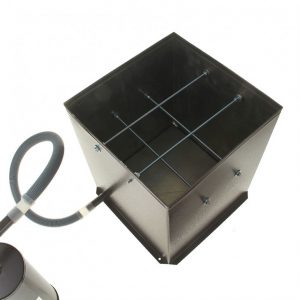

At the place where the smokehouse and the chimney are connected, they put a filter. As the main element, they take a metal mesh with small cells. Dense material is placed on the mesh. The filter protects the finished product from soot.

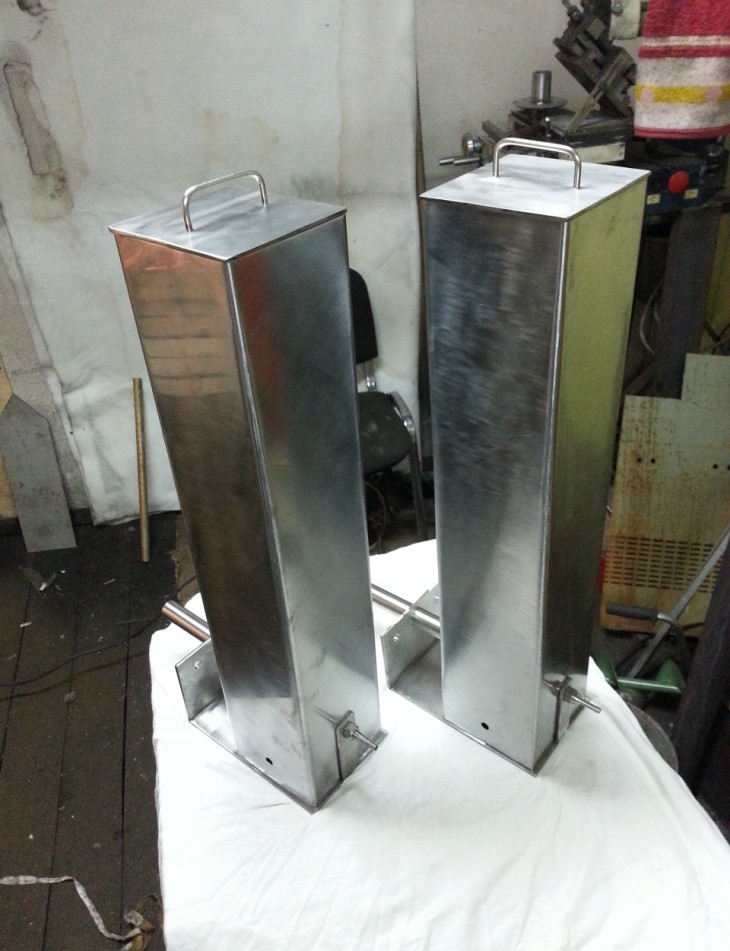

It is important to make the smokehouse strong and reliable. In this case, the structure will stand steady and will not fall if someone accidentally touches it. At the top, the smokehouse is equipped with stainless steel rods.

The indicator of their thickness varies in the range from 8 to 10 mm. They are durable, and they are hung food prepared for smoking. Usually food is hung on special hooks. An alternative replacement is a conventional grill.

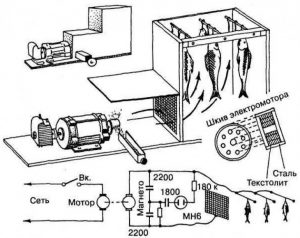

The simplest scheme

A smokehouse is considered a budget option, allowing the master to save building materials and time spent on construction.

The food chamber is 2 meters away from the firebox. A metal barrel can serve as the basis for the smokehouse.

Note!

Work stages

Having determined the size of the smokehouse, you can begin construction. First you need to dig a hole under the furnace chamber.Its bottom is covered with a tin sheet. Thanks to this, it is possible to provide more uniform smoldering of chips and sawdust.

The next stage of work is the installation of the chimney. A dug trench must be covered from above. For this purpose, only non-combustible materials will do.

The pit can be covered with a sheet of slate. Top the chimney is covered with soil to ensure tightness.

The smoking chamber is arranged in a barrel with a cut bottom. A metal mesh is mounted below, on which a burlap is placed. By combining these materials, the problem of filtering soot particles is effectively solved.

At the top of the barrel, a metal grate is bolted to it, stepping back from the edge of 20 cm. This option is optional, you can limit yourself to bars with hooks.

Note!

To fully understand all the nuances, you need to watch the corresponding video clip.

When cold smoked, food loses moisture gradually. During the drying process, smoke penetrates deeper into the products. The result is delicious meat and fish delicacies.

When the carcass of an old animal is smoked, its meat will remain harsh. In order not to be disappointed, at first you need to be guided by recipes that have already been tested by many. Tasteful experiments are best left for later.

In the finished factory-made smokehouse there are several grates and a pallet. It is better to choose a product with a large capacity, so that smoking is carried out more evenly.

For lovers of long trips you need a smokehouse made of metal with a thickness of 0.8 mm. In the country, you can install heavier options, where the thickness of the steel case is 2 mm.

DIY cold smoked smokehouse photo

Note!