If you had an idea to build a house with your own hands, then the difficulty of choosing the material will be relevant.

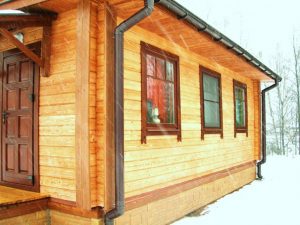

The most budget option is to build a house from a bar. With all the cheapness of this material, the house will turn out to be quite warm, durable and strong.

Having studied the Internet, you will find that in most cases it is advised to choose a beam with a section of 150x150 mm.

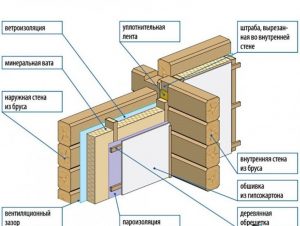

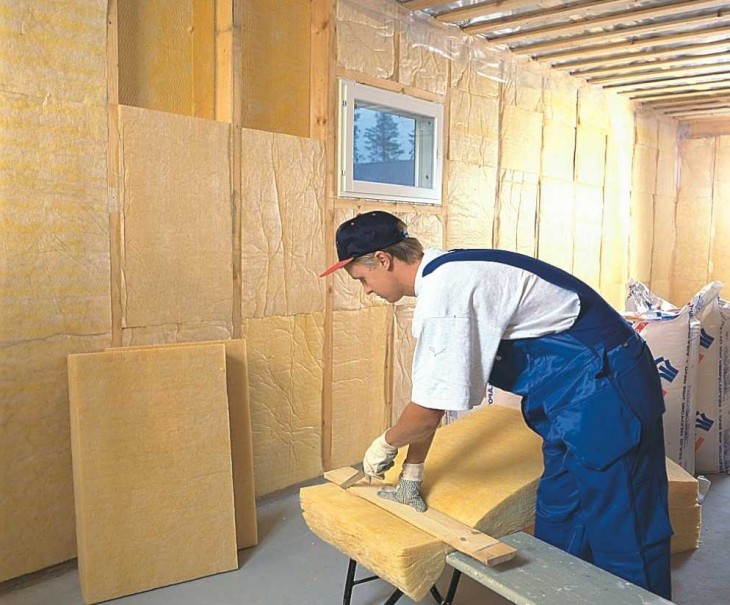

But in the event that you do not want to attract additional labor, lumber such as dry timber 150x100 mm, which after erection and shrinkage can be insulated with mineral wool, is suitable for you. The house will not be inferior in thermal insulation to other buildings from a bar of a larger section.

Review Content:

Stages of construction and foundation

And so, the material is purchased, we proceed to the construction of the house:

- Initially, it is necessary to clear the space and level the site under the foundation;

- In accordance with the composition of the soil, determine the type of foundation (specialized reference books will help).

The foundation can be pile, monolithic or tape, which is more often used, because wooden houses are relatively light.

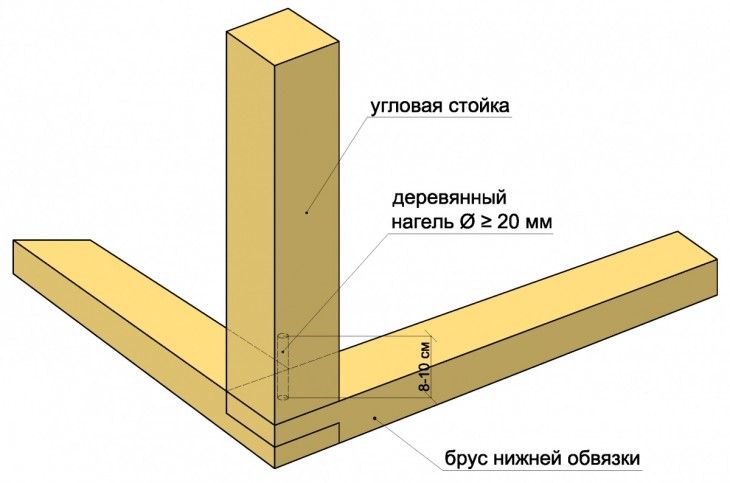

After installing the foundation, the concrete should gain strength (3-4 weeks), then proceed to laying the beam. Even before laying, it is necessary to prepare dowels (dowels) - this is whereby the timber laid in the crowns is fastened together. They are usually made of dense wood (larch).

With a beam size of 150x100 mm, pins with a length of about 12 cm are suitable. Also, the technology of laying the beam requires laying an inter-crown insulation. Usually these are rolled materials such as jute, you can also use tow or moss.

On the advice of specialists, you should use fresh red or peat moss, which has lain for no more than 3 weeks.

The first crown of the future home should be made of larch, which is not subject to decay. For greater reliability, it can be treated with bitumen.

The beam of the first crown is fastened together, a technique known as “half-tree” - they cut along and across the ends of the beam. It is also necessary to fasten such a knot with brackets or nails.

Methods of fastening the beam to the foundation

At the stage of pouring the base, bolts with bent or bases in the form of a cone are mounted in its upper layer. The distance between such bolts should not exceed more than 0.5 m. At least two bolts should fall on each element of the first crown.

In the beam of the first crown, even before laying, it is necessary to drill holes for the studs located in the foundation.

On top of the grillage, a pre-cut roofing material is laid, which acts as a waterproofing material.

Having laid the first crown and securing it on the studs of the foundation with washers and locknuts, bring out the horizontal level so that the house turns out to be distorted. It is also recommended to check the diagonals.

Having laid the first crown, we proceed to the erection of walls.

For this you will need a diverse tool:

Note!

- Gasoline or electric saw;

- Hand circular saw;

- Drill;

- Level;

- Roulette;

- Ax;

- Hammer;

- Screwdriver;

- Hammer drill;

- Plane.

Also, consumables are needed - nails, screws, interventional insulation, fire-retardant impregnations.

After preparing all the necessary materials and tools, we proceed to the erection of the walls of your future home. The timber is laid in rows (crowns) until a wall of the required height is obtained.

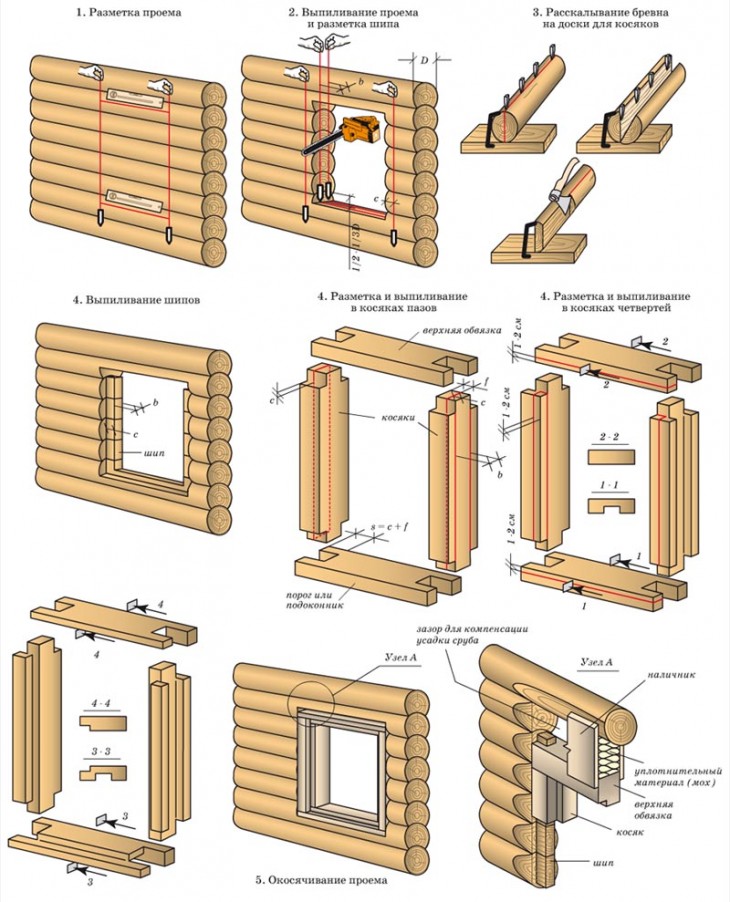

After laying the 4-5 rims, jambs for door and window openings are installed. The next step is the final erection of walls under the roof.

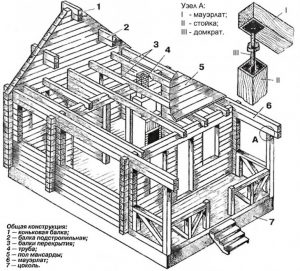

The construction of the roof and floors

Saving on material for installing the roof is strongly discouraged. This part of the house can be performed in several versions:

- Single slope;

- Gable;

- Hip

- Tent;

- Semi-hip;

- Multi-forceps;

- Vaulted and tambourine roofs.

It all depends on your desire, money and the complexity of the rafter system.

Note!

Floors and ceilings in the house is also not an unimportant stage of construction. When arranging them, they are mainly guided by personal preferences, but quality waterproofing is mandatory for any manufacturing option. This is especially true for basements and socles.

In a wooden house, we recommend using penetrating moisture protection, plastering materials or rolled waterproofing. For more details, the process of building a house from a bar is presented in the photo.

DIY home photo from timber

Note!