My home is my castle. And made with your own hands, as in the photo of a wooden house, it will also warm your soul and leave no doubt in reliability and environmental friendliness.

For many centuries, people have built and continue to do this, using wood as a building material.

Indeed, in wooden houses it is warm and comfortable in the winter, and quite fresh in the summer heat.

Review Content:

- Characteristics of building a house made of wood

- Preparation of new design documentation

- Foundation laying

- Determination of type of construction

- Walling

- Roof device

- Windows and doors in a wooden house

- Floor and ceiling in a wooden house

- Home decoration

- Sewerage and plumbing systems

- Heating system

- Electricity device

- Professional advice

- Varieties of home ventilation

- Construction decor

- DIY wooden house photo

Characteristics of building a house made of wood

How to build a simple layman a wooden house with his own hands, we will tell in more detail in our article. And let's start with the main points of construction:

Preparation of new design documentation

This contributes to the presentation of the finished type of construction, thoughtful selection of building materials, prioritization, and paperwork. At this stage, you can think over and solve many of the nuances in terms of organizing work, solving financial issues and design episodes.

Foundation laying

The main and most important moment of building a house, since it accounts for a third of the consumption of materials, a lot of time and effort. But if everything is done correctly, then you are guaranteed a long life of your home.

The site for building a house should be selected based on the geological properties of the soil. Basically, for the construction of a wooden house, a columnar or screw foundation is used.

Columnar - the most popular, as it is durable, not too expensive and quickly erected. Its construction consists of reinforced concrete blocks, stone and brick. The foundation is laid depending on the type of soil and the level of groundwater.

This option not only saves building materials, but also financial means, since it is easy to install it yourself.

Screw implies increased labor costs, without which it is impossible to cope. This option is suitable for mountainous and wooded regions, because the installation of piles and their twisting 2.5 m deep into the earth is required.

After that, the whole structure must be poured with concrete mixture, weld the head and set the top of the foundation.

Determination of type of construction

The most popular are frame houses made of wood. They are the most inexpensive, from 190 dollars per square meter, but excluding communications. Housing from processed round logs will cost you $ 270 per square meter. meter, and from glued into packages of lamels of 460 dollars and above.

The most suitable for building a house are logs 7 m long and 25 cm in diameter. For an average country house, a diameter size of 17 cm is suitable.

Walling

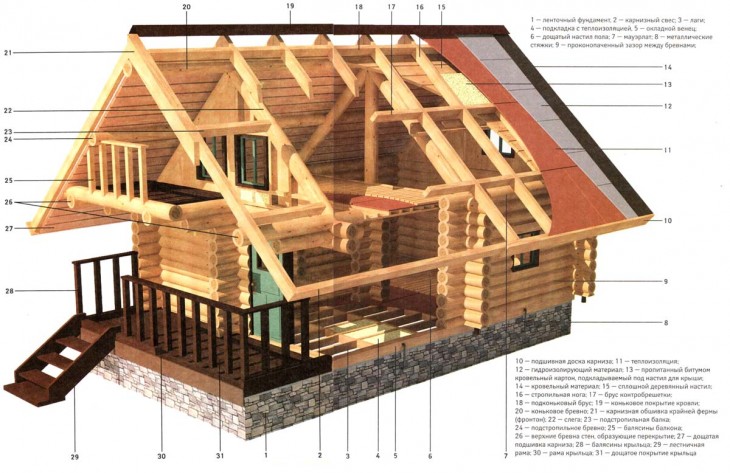

After the foundation has stabilized and settled down, the preparatory work is over, you can begin the construction of walls. To do this, you can use round logs, glued beams or planed, peeled of knots, bark and jagged.

They look great and quite durable thanks to the processing. The tree is harmless to health, although it requires impregnation with a special solution from damage before laying.

Roof device

For the erection of the roof, it is necessary to construct rafters, heat-insulating and waterproofing materials, roofing material.

Note!

The shape of the roof must be chosen correctly so that it protects from the effects of weather conditions and successfully combines with the view of the whole house as a whole.

Today, the choice of material for roofing is quite wide: ondulin, slate, metal tile, corrugated board. As they say, for every taste.

Windows and doors in a wooden house

It’s worthwhile to think over the principle of their work, appearance and other details, and only then build openings for them. Do not forget about the porch or porch to the wooden house.

Floor and ceiling in a wooden house

The floor must be strong, have a long service life and an attractive appearance. Before screeding and flooring, waterproofing must be installed.

![]()

For flooring, linoleum, tile, laminate, carpet or natural wood are usually used. A wooden ceiling should look aesthetically pleasing, electrical communications should be hidden inside.

Home decoration

A wooden house does not need additional decorative elements, with the exception of houses made of simple logs, which will shrink for a long time. Such houses can be ennobled with modern materials.

Note!

Sewerage and plumbing systems

If there are existing water supply networks near the house, then you can legally connect to it and enjoy all the benefits. If not, you will need an autonomous plumbing system, which will be expensive.

The same applies to the sewage system and drainage, but this must be done so as not to damage the foundation and floor.

Heating system

Work on arranging home heating is carried out at the end of construction.

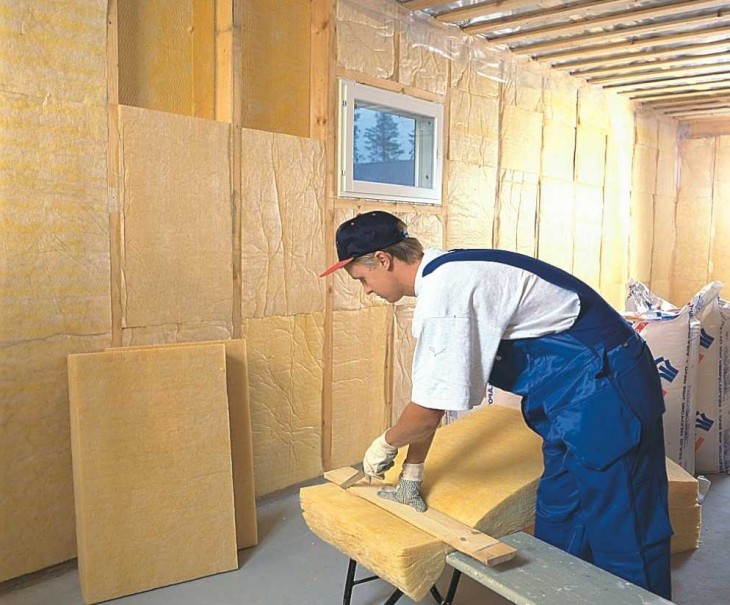

You can afford a warm floor, the use of a gas or electric boiler, stove, etc. Be sure to insulate a wooden house with special heat-insulating materials during construction.

Electricity device

The location of the wiring, nodes, sockets and lighting devices is thought out in detail and calculated in the project of the house, according to which the work is performed.

Note!

The main working moments have been completed, but construction has not yet been completed.

Professional advice

Building a house on your own is a fairly feasible task, but also a responsible one. In order for the final result to please the hosts all their lives, it is worth considering some tips from experienced.

How to make the construction of a wooden house easier and not burdensome for yourself and your handy?

- Calculate all the blanks and details of the future construction. Then install the wreath in the corners with the subsequent connection in half of the tree and secure with nails.

- Install the beam and fasten the crown to the floor. At the end, lay the beams with a gap of 0.7 m, a sealant and again the bars. Make the floor from boards 40 mm thick, and clean thoroughly with a groove board 35 mm thick. For insulation use felt, linen, tow or moss.

- Make a drainage system: cut the upper edge of the beam by 15 mm from the outside.

- When building a house on several floors, the second is constructed at a height of 2.5-3 m, then an attic or attic. Doors mainly prefer paneling, and windows - wooden or metal-plastic.

- For the construction of the roof, a board of such dimensions is suitable: 10x4 cm for racks and braces, 15x4 cm in increments of 1 m for the construction of rafters, unedged to be trimmed 25 mm through 0.4 m.

Varieties of home ventilation

Wood, being a natural living material, can in itself saturate a house with oxygen. But for some rooms (kitchen, bathroom, basement) this is not enough. Therefore, an additional ventilation source is needed.

As a natural exchange of air, air ducts installed on the roof are used. For forced air circulation, special devices with noise insulation can be installed, which will solve the problem with high noise levels.

The ventilation pipe is installed almost to the floor for air flow, and almost under the ceiling for exhaust.

At the entrances to the pipe grilles are installed to protect against rodents, or grids to protect against dust and dirt. In winter, these holes are closed.

Construction decor

If you want to decorate your home with color, you can use special paints taking into account humidity, type of wood and its condition.

When painting the floor in the hallway, do it in several layers, since it is subject to great mechanical stress. Be sure to consider this nuance when painting the floor in other rooms.

The most suitable means for painting wooden boards is oil paint, it is durable and harmless, but dries for a long time. Acrylic and varnish are also widely used.

Cracks in the floor before painting should be puttied using river wedges. Combine irregularities with a planer, prime the surface, dry and paint.

Here, perhaps, all the charms of building a wooden house with your own hands. As you can see, this is not difficult, you just have to want to, show your imagination, make efforts, patience and finances, study some video master classes. Go for it and you will succeed!

DIY wooden house photo