Perhaps, any landowner has a question, how to make a pool with their own hands on its territory.

But before proceeding with the installation of such a tank, you should understand what is the sequence of its manufacture.

There are several types of pools that can be easily built independently, even without a builder’s diploma. The choice of a particular type of pool is often determined by the parameters of the territory allocated for it, and also depends on what season it will be used.

The most popular are prefabricated structures made of plastic or polypropylene, frame pools made of steel, as well as stationary structures with a concrete base.

Numerous photos of existing pools, presented in the network or special catalogs, can help determine the future tank option.

Review Content:

Summer pool for a summer residence

After carrying out preliminary calculations related to the supply of communications, the placement of additional equipment, you can begin to prepare the pit.

It can have any shape, however, the angle of inclination of its walls should not exceed 25 degrees. All its surfaces are carefully leveled and compacted.

To create a waterproofing, a film soldered with a hot iron or stitched tarpaulin is used. One of these materials is lined with the bottom of the tank, previously covered with sand, in order to avoid damage to the waterproofing, and its walls, while going beyond the edges by about 50 cm. The ends of the film or tarpaulin are fixed.

The advantage of such a handmade pool is that its installation is possible on any type of soil, and it is suitable for use in the summer at the cottage.

Draining water from this design is not difficult: the drainage system consists of a hose installed in the lower part of the trench dug at the bottom and a hose located above the water level.

At the end of the season, the tank must be emptied and the insulating material removed for storage.

Pool with concrete bowl

In the manufacture of a stationary pool, the inside of the pit is pre-coated with polyurethane, mineral wool or foam, and then concreted.

The installation diagram of the pool in general terms looks like this:

- concrete laying (approximately 5 cm);

- manufacture of a frame from reinforcement;

- concreting of the bottom and walls;

- the construction of wooden formwork;

- pouring the remaining structure downhill towards the drainage point.

If the staircase for the pool, made of concrete, will be placed inside, then it is built at the same stage. The optimal height of the steps is within 15 cm.

In the upper part of the walls should be provided for the presence of a gutter that will prevent the spreading of water on the surface of the soil.

The final stage is the manufacture of tracks located along the perimeter of the structure.

Water circulation mechanism

Having decided to figure out how to build a pool, the latter must be equipped with a water supply and drainage system. For its best circulation, a skimmer is used, which takes water from the surface of the tank, and inlet nozzles. As a result of using these devices, water is purified and returned to the tank.

Note!

Drainage of the pool is carried out using a drain pipe, built into its bottom. The drainage site is equipped with a grate that does not allow large objects to get into the drain hole.

It is possible to drain water from a pool located in a soil recess using an electric pump.

Waterproofing

In order to protect the tank body from corrosion and increase its service life, it is first waterproofed, which is necessary for both the internal and external parts of the object.

The most vulnerable are the joints of structural elements in which water leakage is possible. Therefore, the need arises for their sealing, which, as a rule, is performed using polymer waterstops. A bentonite cord or sealing profiles may also be used.

Ventilation

If the pool is located indoors, installation of ventilation equipment is necessary. To avoid an increase in evaporation, do not direct the flow of fresh air to the water surface.

Note!

In enclosed spaces with an artificial pond, the use of an air conditioner is highly undesirable.

Finishing work

The inside of the pool bowl is usually tiled or mosaic. A PVC film may also be used.

To strengthen the structure, brickwork is used, decorated with natural or artificial stone.

The original finish is bulk floors, including those with the effect of a three-dimensional image.

The use of lighting

As a common light source, LED lamps and halogen rail lamps are often used. Also, the bottom of the tank is often found, while the lamps are located under water.

Note!

For pools with large parameters, the use of optical fiber is suitable.

Equipment

One of the main and mandatory elements of equipment is a pool filter that purifies water from pollution. This procedure can be carried out continuously, or as needed.

For the same purposes, chemical reagents are used, which in small doses do not pose a danger to human health.

A useful accessory is a dehumidifier, which reduces humidity in a room with a water tank. Heating appliances can also be used here.

Before starting to use the pool, it is necessary to draw water into it, check for leaks and filter the water, after which it is possible to make the first swim with pleasure.

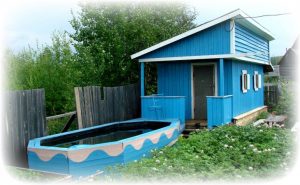

DIY pool photo